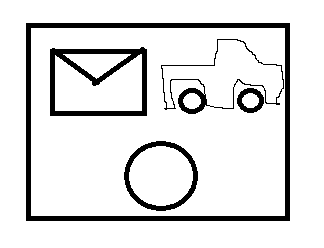

What started out as a dedicated piece of hardware for a driveway and mailbox sensor has since turned into a quick message board for me to pass love notes to my wife during the day.

Demo Video

Backstory

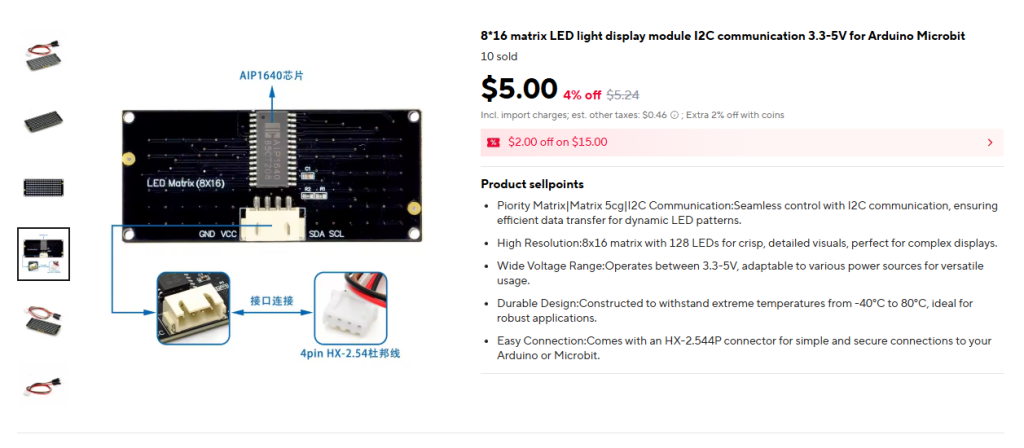

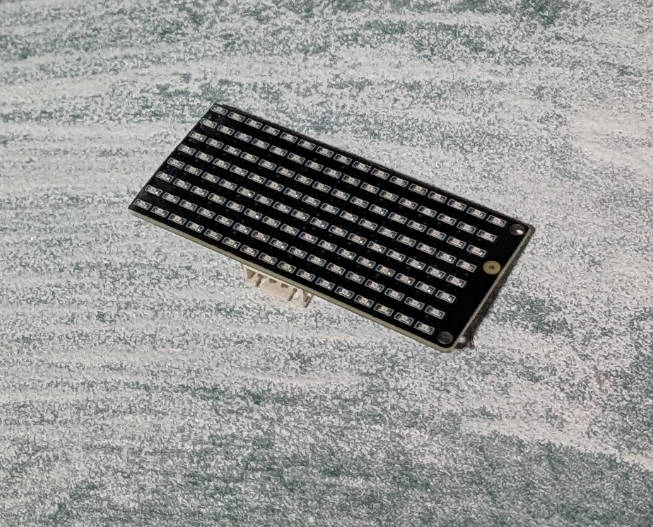

A few years ago I purchased a set of 4x of these 8×16 LED displays after watching a video by Upir.

I was inspired to make a binary clock with a custom aperture made on my bambulab printer (super exciting, this multiple-filament business). It was a fun start and honestly a good excuse to vibe code up some real-world displays. I wanted a desktop toy that I could power with an ESP32 and display the time, weather, and some other data.

This was shortly before I decided on the CRT Weather Display as my primary project for 2025. These LED panels quickly got shelved.

Fast forward to 2025 and my wife and I had a second kid, bought a house, and are now dealing with a long walk to the mailbox and no way to tell if someone is coming up our driveway.

Like Chekhov’s Gun these little panels sat in my box full of random project parts for a little over two years only to meet their fate last night.

Beginning

The idea came to me as I was exploring options for notifying the household of mail or a vehicle coming up my driveway. Why not have a dedicated art piece that contains a bell, and a set of icons for discerning between us getting mail and a car driving up the road? Light up the mail icon for mail and the truck icon for road. This would let me use those panels I bought so long ago (and make custom light masks on my 3D printer again!) I’m losing money if I don’t buy the bell for this project!

I got the bell on order from AliExpress as the Amazon options were quite limited and honestly too large for my need. I would have chosen a smaller bell, but lacked the search terms to find something smaller and cheaper. In hindsight an unpowered children’s bicycle bell would have probably worked just fine!

Once the bell arrived I tested it out and it quickly found a spot on my shelf next to all the other project parts I’ll definitely get to some day. I didn’t quite like the way it clanged like a fire alarm so I needed to brainstorm solutions for that.

The bell then sat dormant for the next four months.

I’m on a Roll!

Since it’s winter, a lot of my outdoor home improvement tasks have been put on hold while I wait out the rain here in the Pacific Northwest. I had a few mission critical tasks I needed to sort out before I could get to the notifier however. Through some miracle, my 5 backburner projects have all been completed or in a state where I was out of excuses for not working on this one.

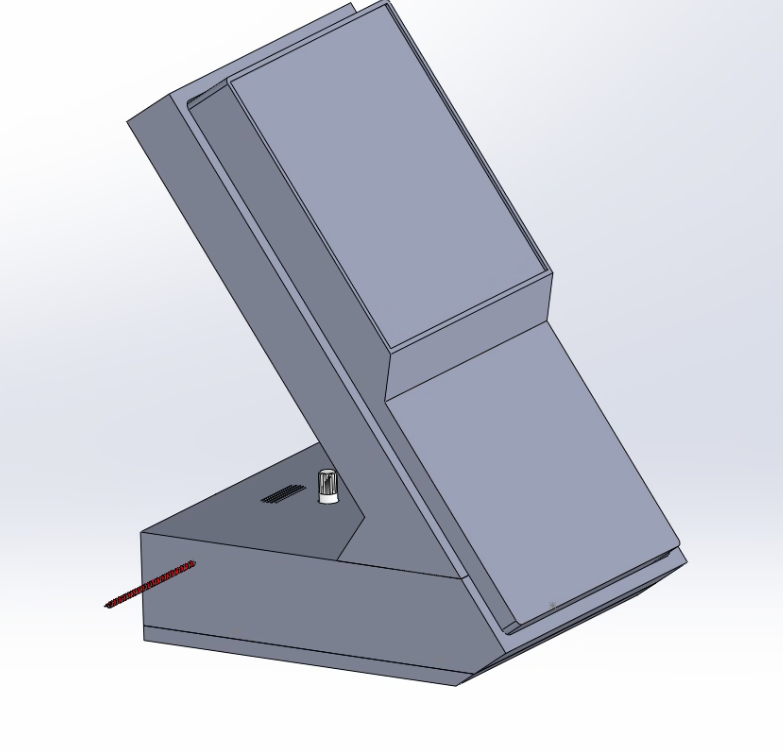

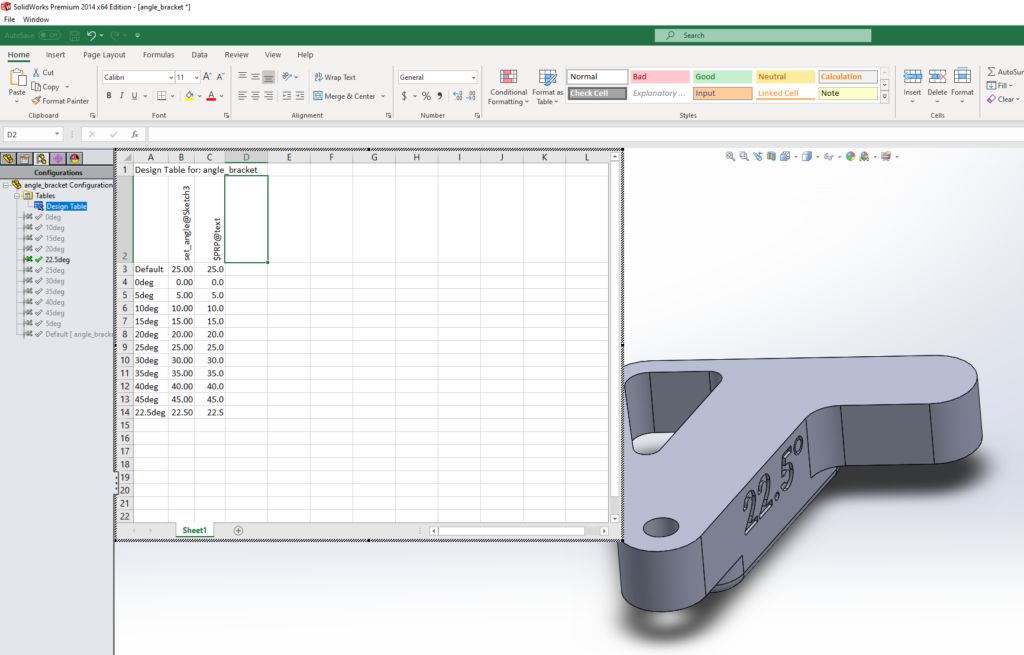

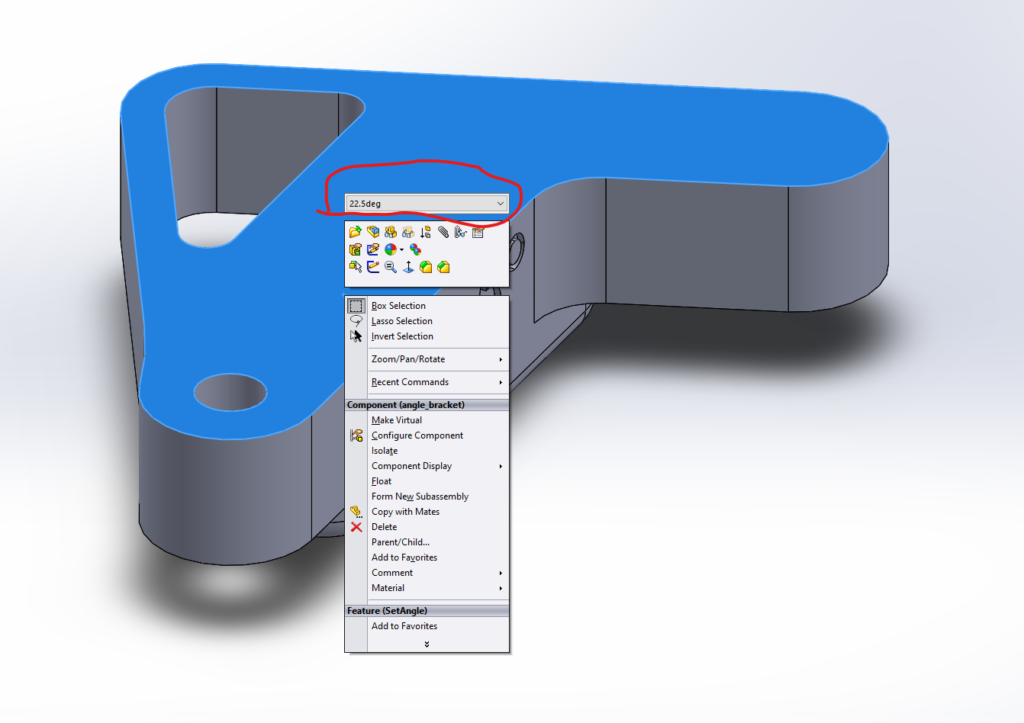

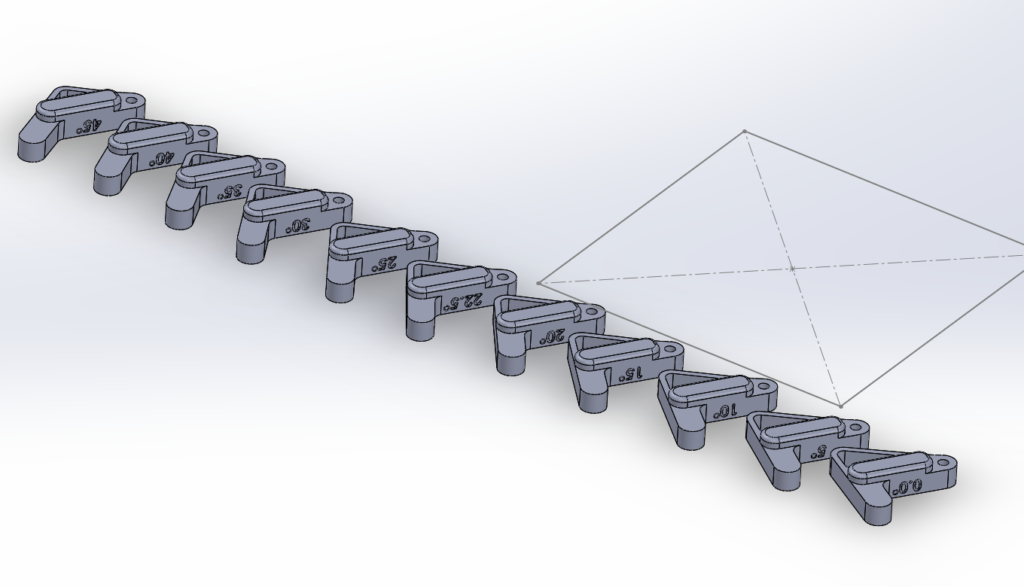

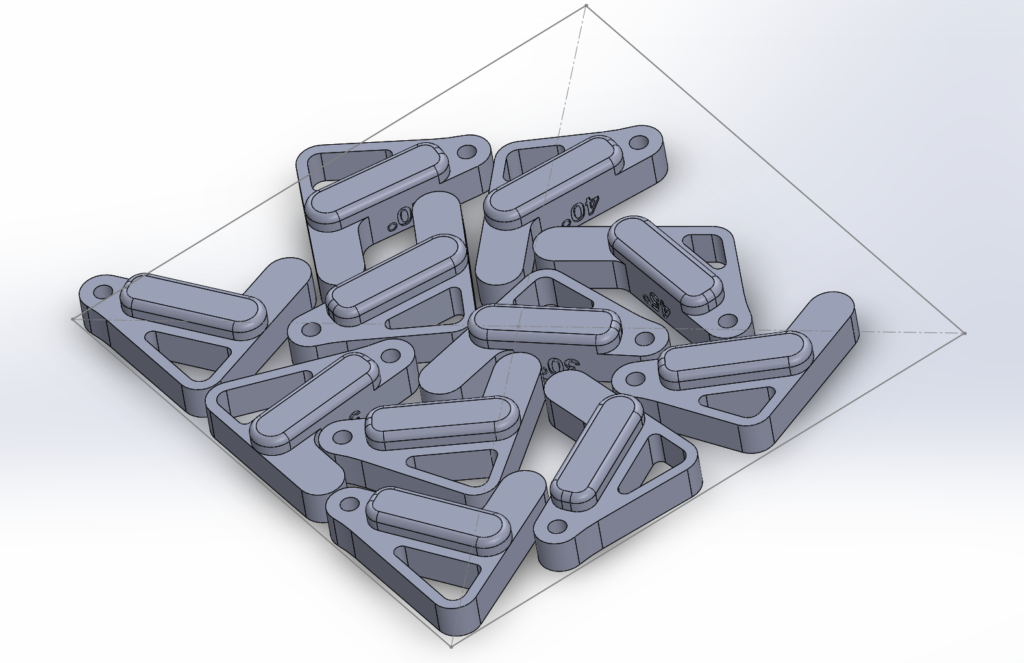

With the long President’s day weekend ahead of me I began drafting my idea in Solidworks. I designed a simple, bi-color proof of concept unit that I could hang on a wall and test fit around the house.

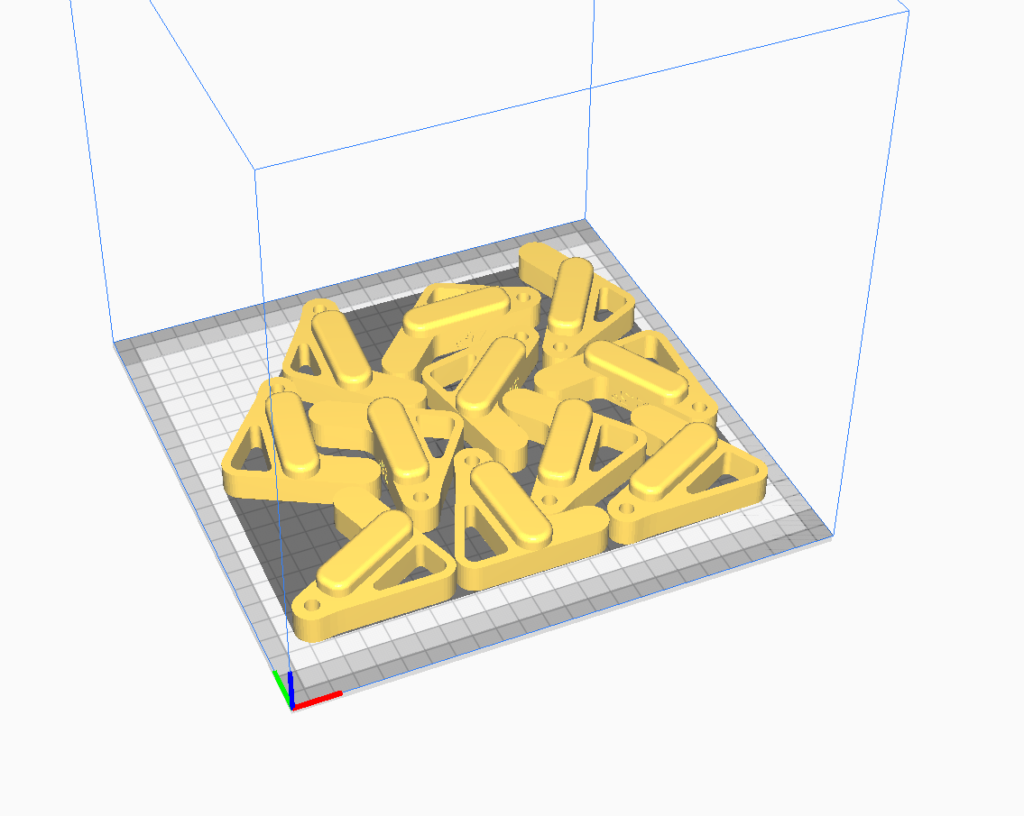

The first problem this design highlighted was how freaking large it was! I could not get the whole thing to fit on the bed of my printer so I had to cut it into pieces and glue them together later.

Quick Side Bar

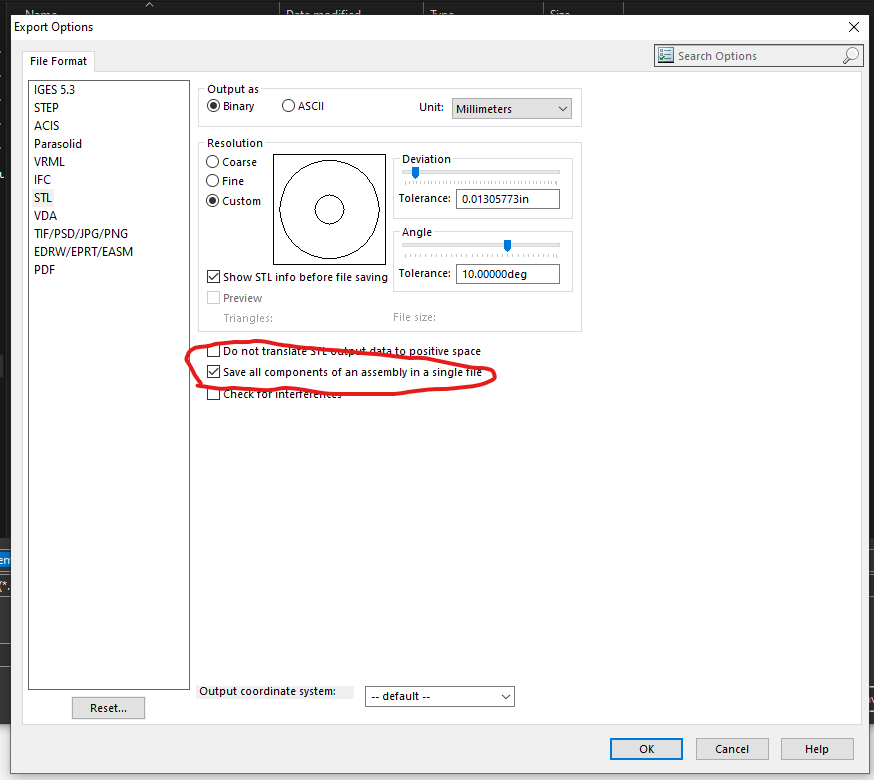

In order to cut the model into pieces I used the Split command in solidworks. This turned my singular part into multiple bodies. To make 3D printing easier (one filament per body) I also unchecked “Merge result” in my boss extrudes. I was then left with four bodies to export as STEP files. To do this manually (at least in SW2014) is SUPER TEDIOUS. The user has to delete the unused bodies, save the single body as a STEP, undo the delete, and re-delete a new set of bodies for the next save. This quickly got old so I turned to the internet plagiarism machine to help me write my first macro. With a little debugging I actually got functional code and a macro that exports all bodies in a part within seconds! I also stole/made a macro for multi-body STL files, but don’t like how STL handles curves. Both macros are posted below. The STL macro is tailored to put the output files into C:\Users\solidworks\Desktop\Conrads Projects\Multi_Body_STL_Exports be sure to change this for your setup!

MULTI-BODY STEP EXPORTER MACRO

Option Explicit

' --- numeric constants ---

Const swDocPART = 1

Const swExportSTEP = 6

Const swSaveAsCurrentVersion = 0

Const swSaveAsOptions_Silent = 2

Const swSaveAsOptions_Copy = 8

Const TEMPLATE_PATH = "C:\ProgramData\SolidWorks\SolidWorks 2014\templates\Part.prtdot"

Dim swApp As Object

Dim src As Object ' ModelDoc2 (source part)

Dim BodyArr As Variant

Sub main()

Set swApp = Application.SldWorks

Set src = swApp.ActiveDoc

If src Is Nothing Then Exit Sub

If src.GetType <> swDocPART Then

MsgBox "Open a PART document.", vbExclamation

Exit Sub

End If

' If the part isn't saved, we'll export to Desktop

' (no need to exit)

Dim saveDir As String

If src.GetPathName <> "" Then

saveDir = Left(src.GetPathName, InStrRev(src.GetPathName, "\") - 1)

Else

Dim wsh As Object: Set wsh = CreateObject("WScript.Shell")

saveDir = wsh.SpecialFolders("Desktop")

End If

If Dir(saveDir, vbDirectory) = vbNullString Then MkDir saveDir

' get all bodies in the source part

BodyArr = src.GetBodies2(0, False)

If IsEmpty(BodyArr) Then

MsgBox "No bodies found.", vbExclamation

Exit Sub

End If

Dim i As Long, swBody As Object

Dim exported As Long, failed As Long

For i = 0 To UBound(BodyArr)

Set swBody = BodyArr(i)

If swBody Is Nothing Then GoTo NextI

' --- create a brand-new part and INSERT the body without selection ---

Dim partTplt As String: partTplt = TEMPLATE_PATH

If partTplt = "" Then

MsgBox "Set a default Part template in SW Options > Default Templates.", vbExclamation

Exit Sub

End If

Dim tmp As Object

Set tmp = swApp.NewDocument(partTplt, 0, 0, 0)

If tmp Is Nothing Then

failed = failed + 1: GoTo NextI

End If

' Copy the body and insert via CreateFeatureFromBody3 (bulletproof in SW2014)

Dim freeBody As Object

On Error Resume Next

Set freeBody = swBody.Copy

On Error GoTo 0

If freeBody Is Nothing Then

' fall back: try using original body reference

Set freeBody = swBody

End If

Dim partIf As Object

Set partIf = tmp ' IPartDoc late-bound

Dim feat As Object

On Error Resume Next

Set feat = partIf.CreateFeatureFromBody3(freeBody, False, 0)

On Error GoTo 0

If feat Is Nothing Then

' nothing inserted; close and mark failed

On Error Resume Next: swApp.CloseDoc tmp.GetTitle: On Error GoTo 0

failed = failed + 1: GoTo NextI

End If

SafeRebuild tmp

If Not HasBodies(tmp) Then

On Error Resume Next: swApp.CloseDoc tmp.GetTitle: On Error GoTo 0

failed = failed + 1: GoTo NextI

End If

' STEP export options (late bound)

Dim expData As Object

Set expData = swApp.GetExportFileData(swExportSTEP)

On Error Resume Next

expData.AP214 = True

expData.ExportSketchEntities = False

expData.ExportAnnotations = False

On Error GoTo 0

' filename and export

Dim base As String, outPath As String

base = Format(i, "000") & "_" & SafeName(swBody.Name)

outPath = saveDir & "\" & base & ".step"

Dim longstatus As Long, longwarnings As Long, ok As Boolean

longstatus = 0: longwarnings = 0

ok = tmp.Extension.SaveAs( _

outPath, _

swSaveAsCurrentVersion, _

swSaveAsOptions_Silent Or swSaveAsOptions_Copy, _

expData, _

longstatus, _

longwarnings)

' close temp part regardless

On Error Resume Next

swApp.CloseDoc tmp.GetTitle

On Error GoTo 0

If ok Then exported = exported + 1 Else failed = failed + 1

NextI:

Next

src.ClearSelection2 True

MsgBox "STEP export complete. Exported: " & exported & ", Failed: " & failed & vbCrLf & _

"Folder: " & saveDir, vbInformation

End Sub

Private Sub SafeRebuild(ByVal mdl As Object)

On Error Resume Next

mdl.EditRebuild3

On Error GoTo 0

End Sub

Private Function HasBodies(ByVal mdl As Object) As Boolean

On Error Resume Next

Dim arr As Variant

arr = mdl.GetBodies2(0, False)

HasBodies = Not IsEmpty(arr)

On Error GoTo 0

End Function

Private Function SafeName(ByVal s As String) As String

Dim bad As Variant, r As Variant

bad = Array("\", "/", ":", "*", "?", Chr$(34), "<", ">", "|")

For Each r In bad

s = Replace$(s, CStr(r), "_")

Next

If Len(Trim$(s)) = 0 Then s = "Body"

SafeName = s

End Function

Private Function GetDefaultPartTemplate(app As Object) As String

' Try SolidWorks default template setting first

On Error Resume Next

Dim p As String

p = app.GetUserPreferenceStringValue(2) ' swDefaultTemplatePart

On Error GoTo 0

If Len(p) > 0 And Len(Dir$(p)) > 0 Then

GetDefaultPartTemplate = p

Exit Function

End If

' Try a few common install paths (adjust if needed)

Dim c As Variant

Dim candidates As Variant

candidates = Array( _

"C:\ProgramData\SolidWorks\SOLIDWORKS 2014\templates\Part.prtdot", _

"C:\ProgramData\SolidWorks\SolidWorks 2014\templates\Part.prtdot", _

"C:\ProgramData\SolidWorks\SolidWorks 2013\templates\Part.prtdot", _

"C:\ProgramData\SolidWorks\SOLIDWORKS 2015\templates\Part.prtdot")

For Each c In candidates

If Len(Dir$(c)) > 0 Then

GetDefaultPartTemplate = CStr(c)

Exit Function

End If

Next

' Last resort: prompt user to paste a template path

Dim userPath As String

userPath = InputBox("Enter the full path to a Part template (*.prtdot)", _

"Select Part Template", _

"C:\ProgramData\SolidWorks\SOLIDWORKS 2014\templates\Part.prtdot")

If Len(userPath) > 0 And Len(Dir$(userPath)) > 0 Then

GetDefaultPartTemplate = userPath

Else

GetDefaultPartTemplate = ""

End If

End FunctionMULTI-BODY STL EXPORTER MACRO

Dim swApp As Object

Dim Part As Object

Dim boolstatus As Boolean

Dim longstatus As Long, longwarnings As Long

Dim MyPath As String

Dim MyDate As String

Dim MyFilename As String

Dim MySaveasDir As String

Dim Cnt As Integer

Dim Body_Vis_States() As Boolean

Dim BodyArr As Variant

Sub main()

Set swApp = Application.SldWorks

Set Part = swApp.ActiveDoc

Dim myModelView As Object

Set myModelView = Part.ActiveView

myModelView.FrameState = swWindowState_e.swWindowMaximized

‘ Gets folder path of current part

MyPath = Left(Part.GetPathName, InStrRev(Part.GetPathName, “\”) – 1)

‘ Used to create a directory for the STL file with a date code

MyDate = Format(Now(), “yyyy-mm-dd”)

‘ Uncomment this line for STL files to use same file name as the part file

‘ MyFilename = Left(Part.GetTitle(), InStrRev(Part.GetTitle(), “.”) – 1)

‘ Uncomment this line to have the user set the name of the STL files

‘ MyFilename = InputBox(“Set the name for the STL file(s)”)

‘ Sets the directory to store the STL files, I like this format but it can be changed

‘ MySaveasDir = “C:\Users\solidworks\Desktop\Conrads Projects\Multi_Body_STL_Exports” ‘

MySaveasDir = MyPath

‘ checks if MySaveAsDir directory exists, if not it will create one, otherwise an error will occur

If Dir(MySaveasDir, vbDirectory) = vbNullString Then

MkDir (MySaveasDir)

‘ MsgBox “Folder ” & MySaveasDir & ” Created”

End If

‘ creates an array of all the bodies in the current part

BodyArr = Part.GetBodies2(0, False)

‘ Get current visibility state of all bodies, put into an array

For Cnt = 0 To UBound(BodyArr)

Set swBody = BodyArr(Cnt)

If Not swBody Is Nothing Then

ReDim Preserve Body_Vis_States(0 To Cnt)

Body_Vis_States(Cnt) = swBody.Visible

‘ MsgBox (“Body ” & Cnt & ” Visibility: ” & Body_Vis_States(Cnt))

End If

Next Cnt

‘ Hide all bodies

For Cnt = 0 To UBound(BodyArr)

Set swBody = BodyArr(Cnt)

If Not swBody Is Nothing Then

swBody.HideBody (True)

‘ MsgBox (“Body ” & Cnt & ” Hidden”)

End If

Next Cnt

‘ Show each body one by one, save as STL, then hide again

For Cnt = 0 To UBound(BodyArr)

Set swBody = BodyArr(Cnt)

If Not swBody Is Nothing Then

swBody.HideBody (False)

longstatus = Part.SaveAs3(MySaveasDir & “\” & swBody.Name & “.stl”, 0, 2) ‘

‘ MsgBox (VarType(BodyArr(Cnt)))

swBody.HideBody (True)

End If

Next Cnt

‘ Put bodies back in the original visibility state

For Cnt = 0 To UBound(BodyArr)

Set swBody = BodyArr(Cnt)

If Not swBody Is Nothing Then

swBody.HideBody (Not Body_Vis_States(Cnt))

End If

Next Cnt

‘ Open the window containing the STLs

‘ Shell “explorer.exe ” & MySaveasDir & “\”, vbNormalFocus

End Sub

Mechanical Design

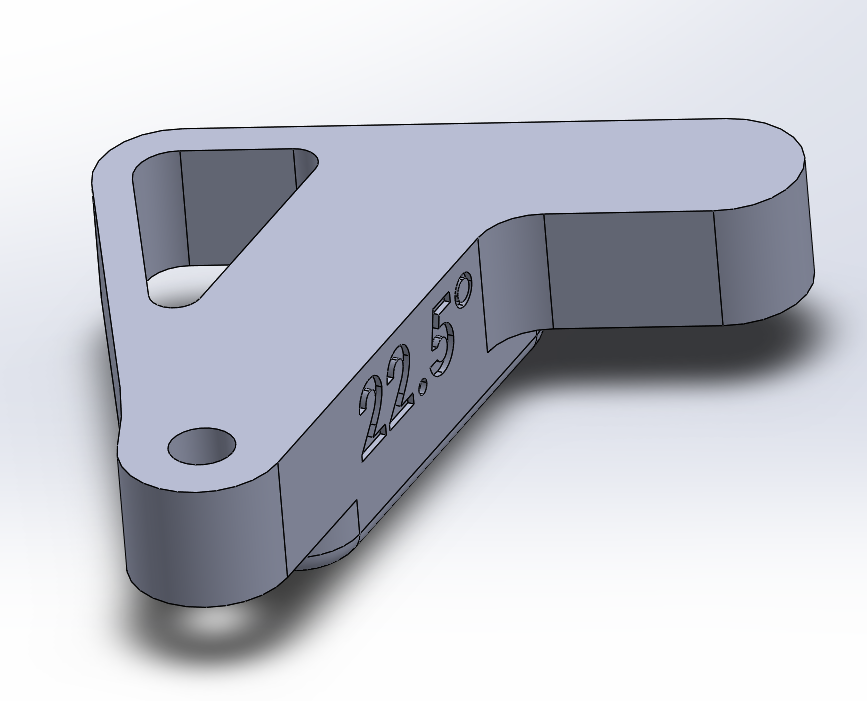

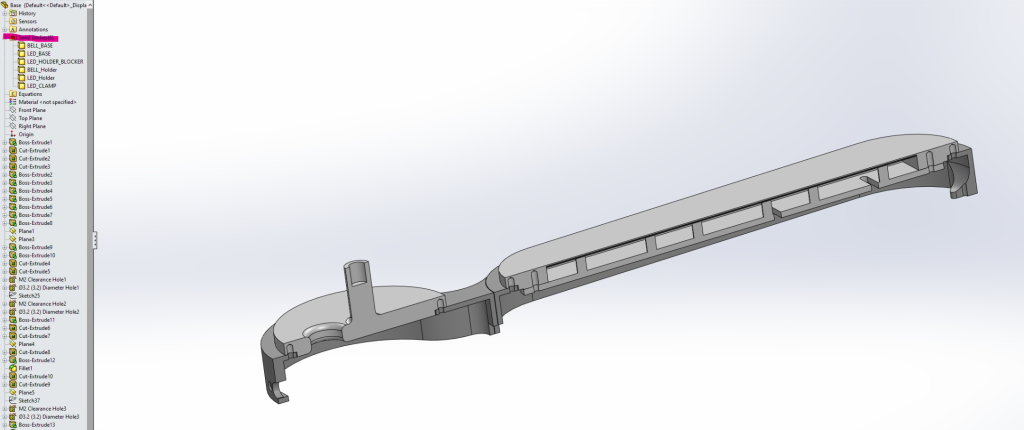

I’m sure this is a lack of user experience, but I first tried to make a new part for each 3D print in the assembly. I started out with the base and included cutouts for the white prints. I then added a new part directly to the assembly and referenced the base for the new part’s dimensions. I quickly discovered that changing the dimensions of the base did NOT change the dimensions of the new part. This was going to get out of hand quick. I could have the whole model built up and a single dimension change could wreck fitment for all subsequent models. Instead I took a different approach, one that I’ve seen Fusion users do a lot of: I modeled all 3D prints in a single solidpart file and made sure to make them separate bodies. Since all the parts refence geometry in the same solidpart file any underlying geometry changes will influence the other parts. 10/10 strategy. For clarity, I still had an assembly with non-3D printed parts that I could use for dimensioning off of so I’m not 100% out of the external reference woods.

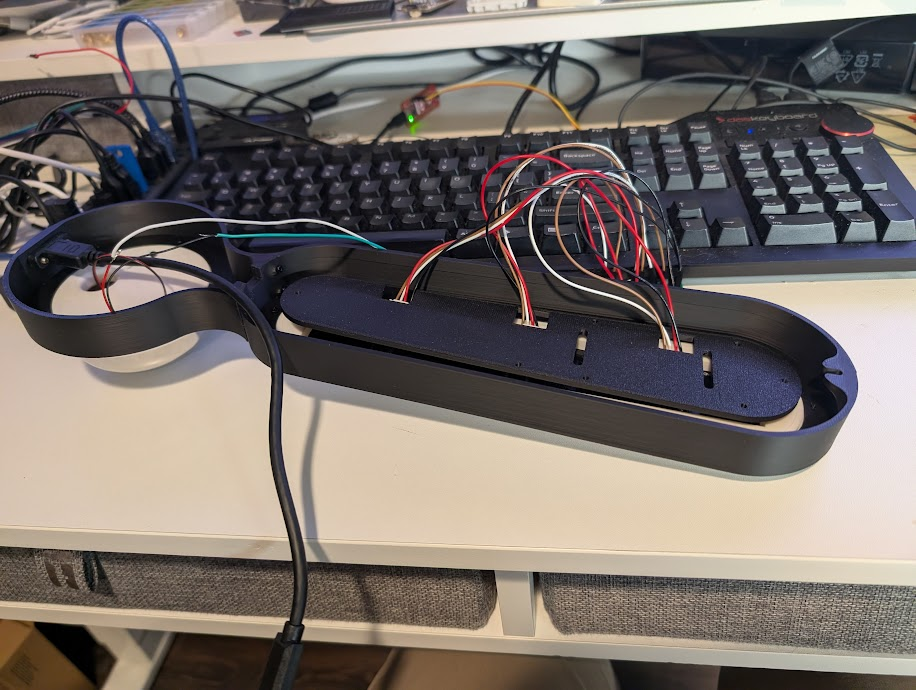

The design was centered around that freaking massive bell I ordered. Luckily I was able to split the prints around each major component (the bell and the LED panels).

3D printing went smooth. The black slender part of the exclamation mark did suffer from warping so I re-printed it with 65C bed instead of 55C and that solved all my warping issues.

Real Quick, I’ll go through all of the 3D Prints and their purpose.

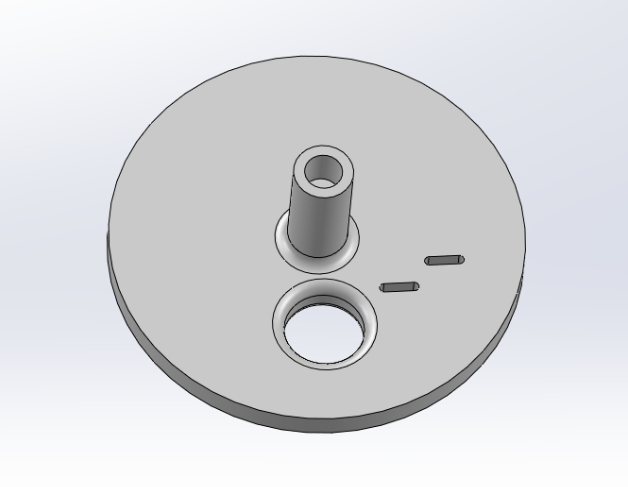

BELL_BASE

This part contains the USB C bulkhead, and clearance holes for attaching the BELL_Holder. It also contains 4x holes for heat-set inserts. This let’s us attach the BELL_BASE to the LED_BASE.

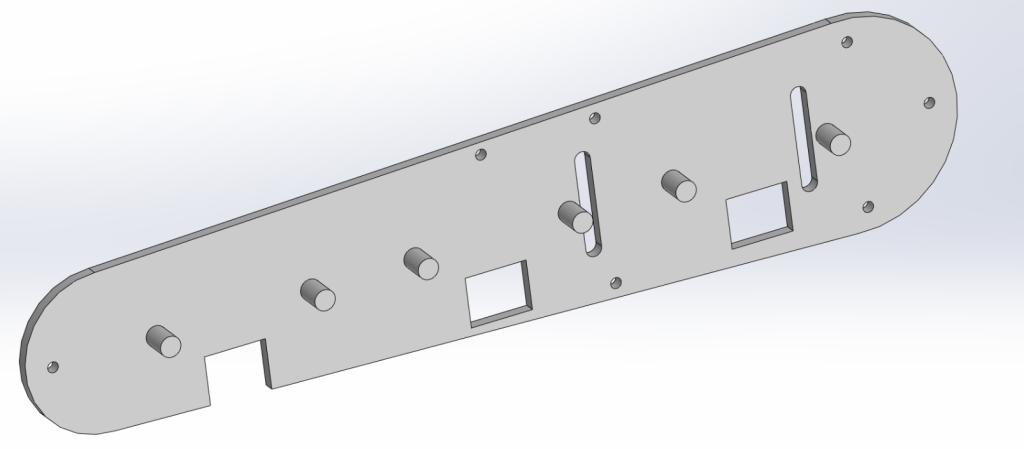

LED_BASE

The LED_BASE contains clearance holes for attaching to the BELL_BASE and for the LED_Holder. It also contains a feature for wall-mounting that’s 3D printer friendly.

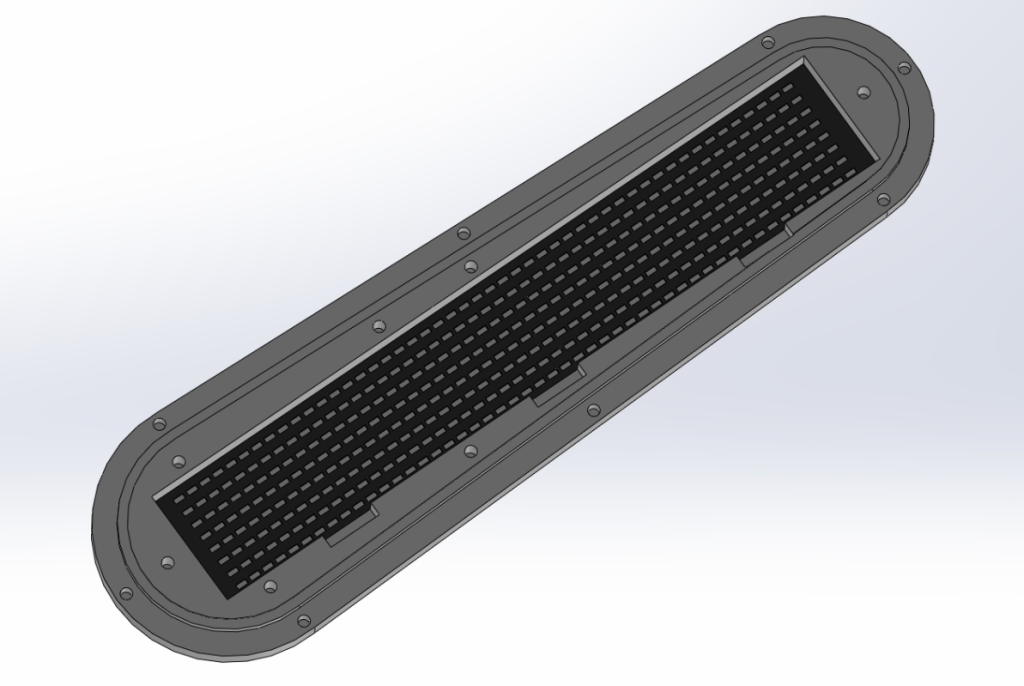

LED_HOLDER_BLOCKER and LED_Holder

This is a multi-color print. I wanted to get around the light bleed so I could have nice crisp pixels but honestly I don’t think it mattered as much and the black light shield shows up through the print like Cousin Eddie’s dickey.

This gets printed as one piece, you can just set the color of the blocker to white as well and you won’t get such an ugly print. I’m not going to do that because there’s approximately 15 heat-set inserts I would need to throw out.

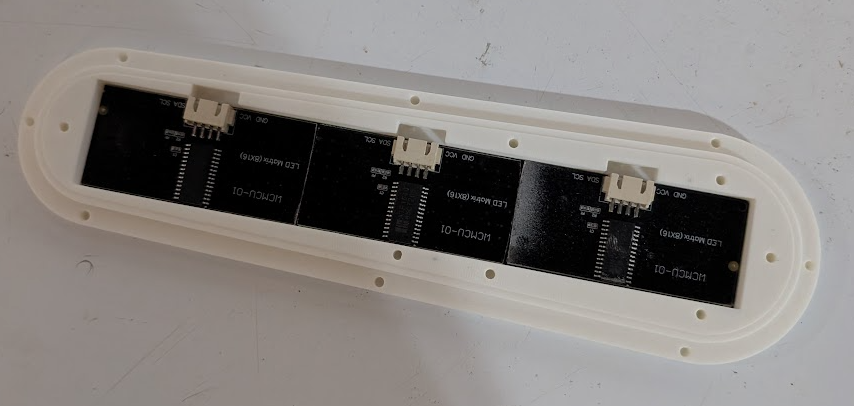

To test fitment I did 3D print the whole piece and a cutaway view so I could see any tolerancing issues I had with the LED panels (there were none!)

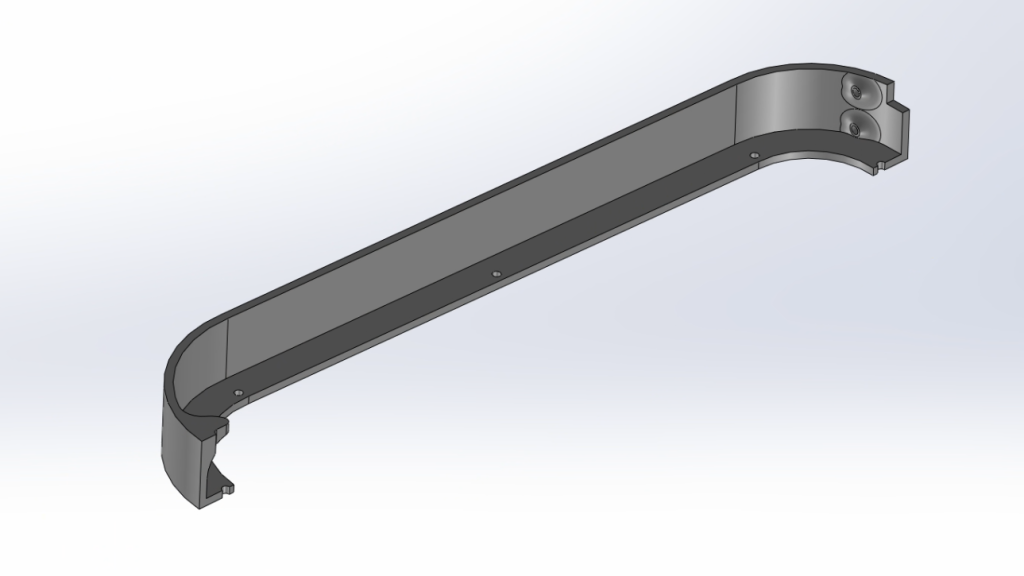

BELL_Holder

The bell holder does what the name describes. It holds the bell. There’s two slots for positioning a 12V solenoid, a hole for fishing the solenoid up through, a heat-set insert hole for the bell bolt and 4x 2mm heat-set inserts on the bottom for attaching to the BELL_BASE. The only unpopular thing about this part is there’s no good orientation to print it. There’s a lip at the bottom to center it in the BELL_BASE. I suppose this lip could be removed but with it in, you need to enable supports and it looks kind of crappy coming off the printer.

LED_CLAMP

The LED_CLAMP does what the name implies, it clamps the LED panels to the LED_Holder. I didn’t want to glue the panels in. I also wanted hooks in place for zip-tying my proto board to the unit as a whole as that bit was an after-though. The squares on the print are for feeding through the wires. I really should have left them as cutouts so you can install this and then fish the wires around. It’s a bit fiddley.

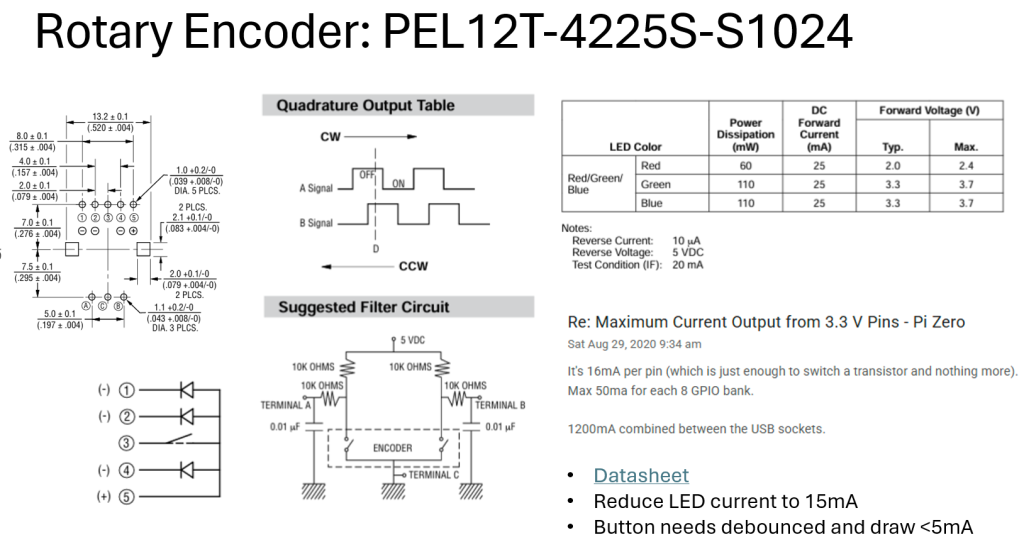

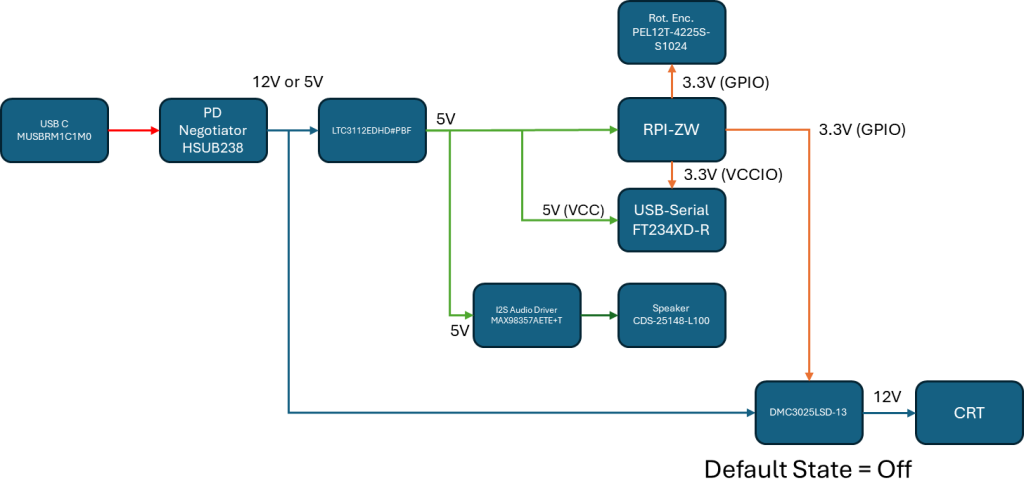

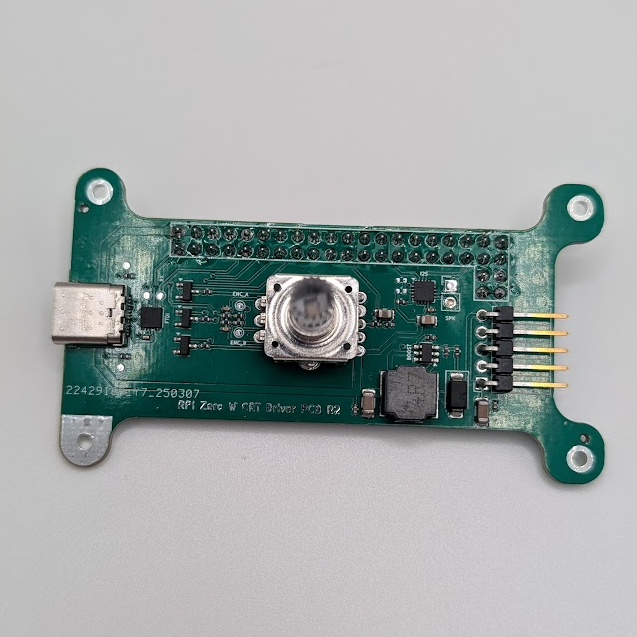

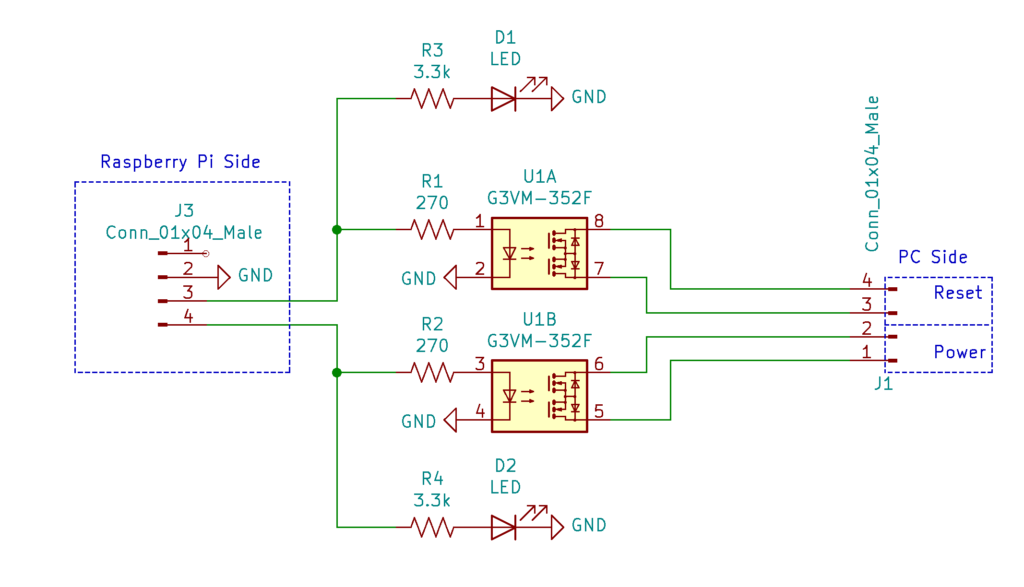

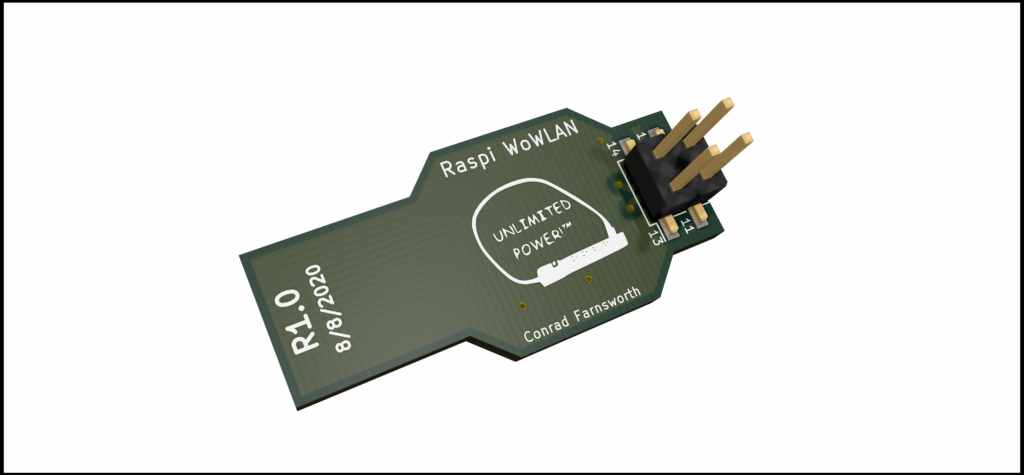

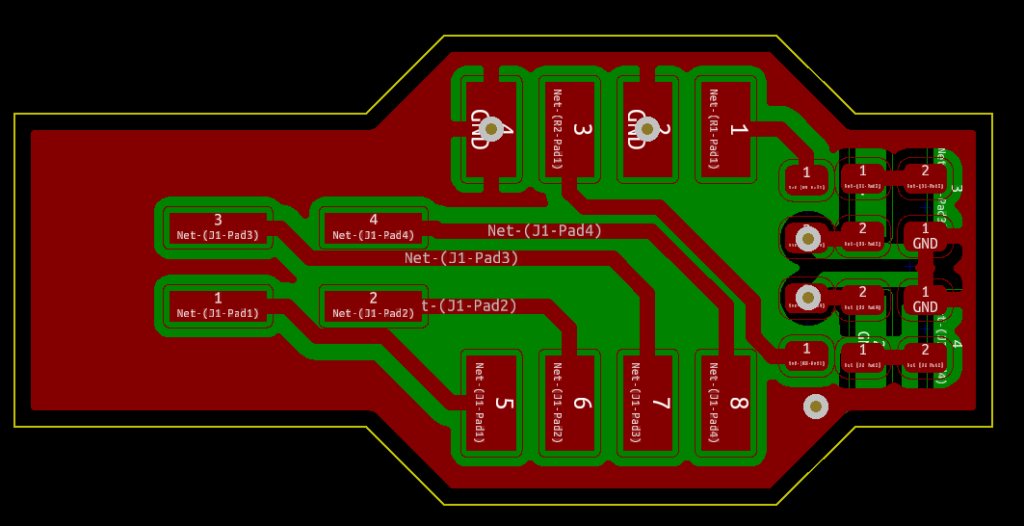

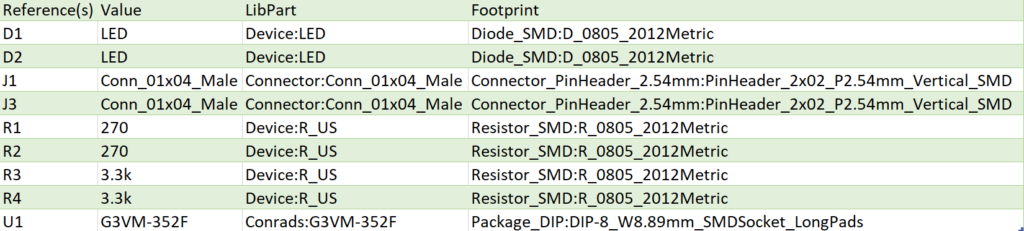

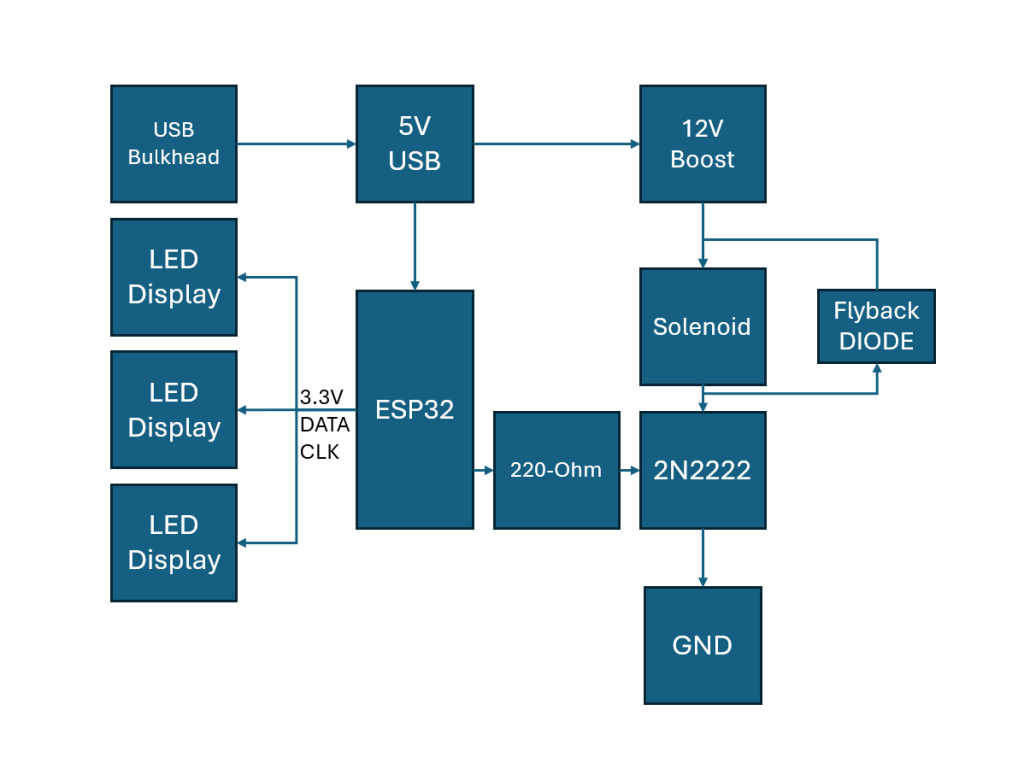

Electrical Design

I had a lot of fun just throwing shit on to a proto board. Normally I would do a PCB but at the time of doing this project I have five concurrent PCB projects going at work and at home and am a bit burned out. I’m also learning Altium for work so my brain is just…full. The best you’ll get is a Powerpoint drawing of everything.

Nothing super special here. The solenoid draws like 200mA always-on. The ESP32 does have a current limit so we’re actually close to not being in saturation. Practically, I don’t see any issues with this.

The LED displays run on 3.3V power from the ESP32 and I was worried about the linear regulator providing power for 3 full panels and the on-board WiFi. I put the panels into a test mode (full on) and left them powered for about an hour. No noticeable heating to the voltage regulator.

Other Parts (Amazon Links and AliExpress Links)

| Item | Quantity | Note |

| 12V Solenoid | 1 | |

| LED Panel | 4 | |

| Bell | ||

| M2 Screws | A Few | Various sizes, test fitment. |

| M2 Heat Set Insert | A Few | |

| M6 Heat Set Insert | 1 | bell mount |

| Proto Board | 1 | |

| ESP32 Dev Board | 1 | |

| 2N2222 NPN | 1 | Some random 2N2222 I had in a kit |

| Diode | 1 | Some random diode I had laying around. No link here. |

| Silicone Wire | 1 | 28GA is what I use. |

| Boost Converter | 1 | 20 Pack |

| USB Bulkhead | 1 | Tight fit, but the screws seat it firmly in place |

| 80-grit sand paper | 1 |

Other Notes

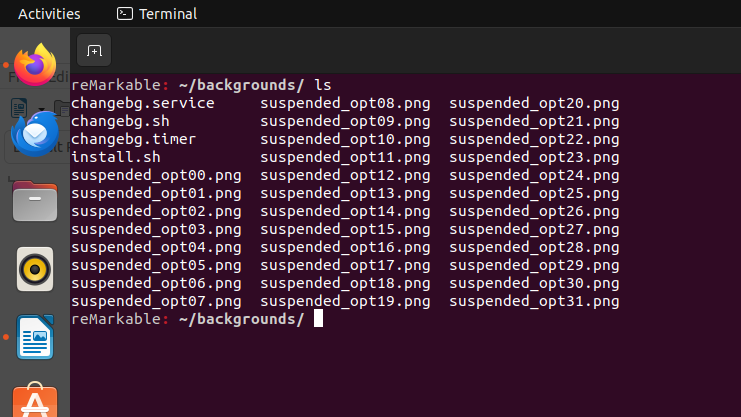

The only real work/modifications that need done are the proto board needed trimmed down to fit inside the “!” and the LED panels needed sanded down to fit in a nice-uninterrupted row.

The LED board can safely be sanded down along it’s length. Unfortunately given the pitch of the LEDs you need to get quite close to them. Take sanding slow and it’ll all go well. I’ve also included extra length for the top and bottom panels so you only have to sand 4x sides instead of 6x sides.

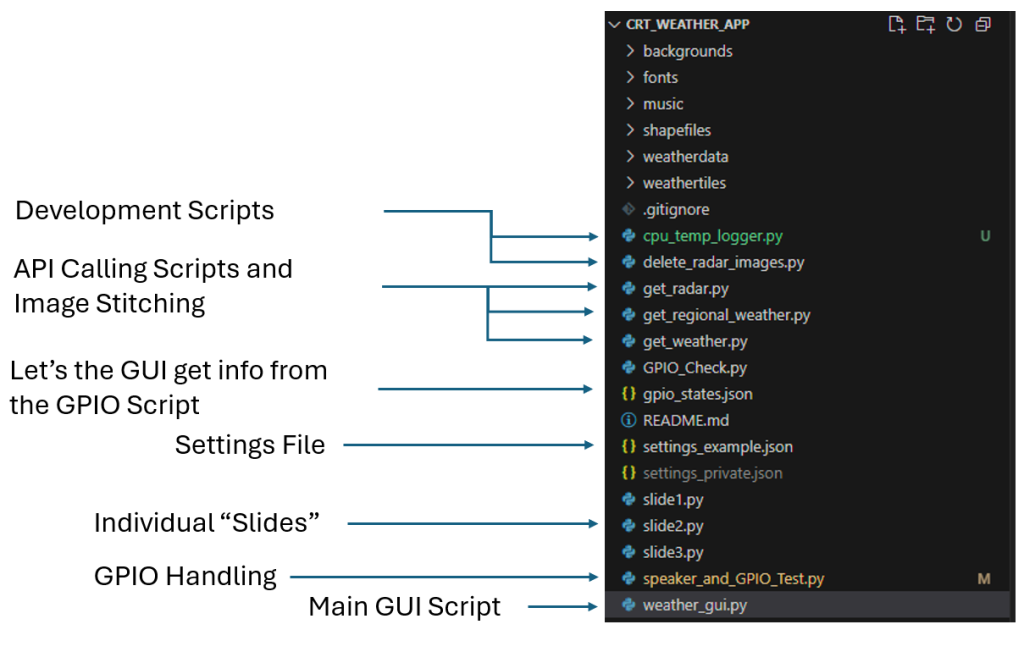

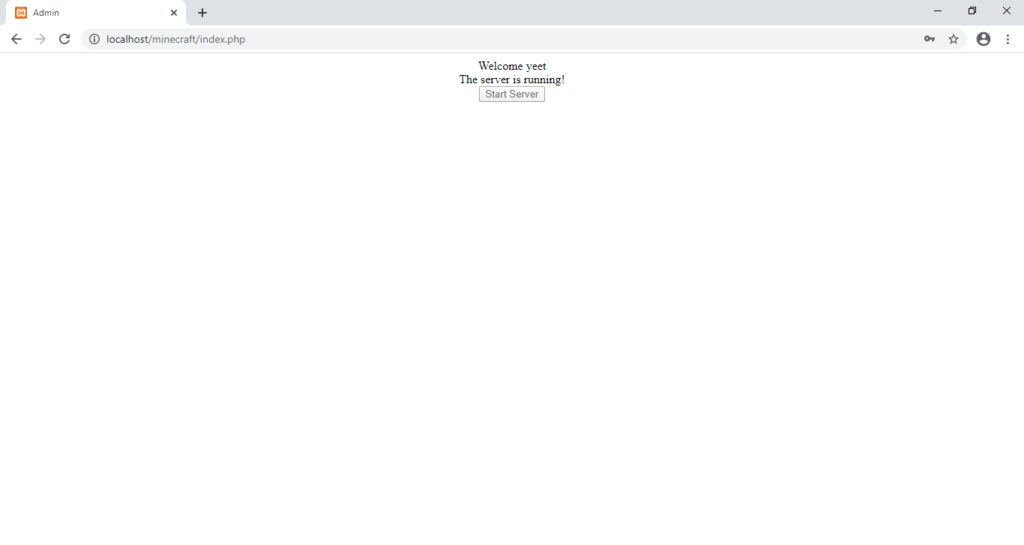

Code

Disclaimer: This was 100% vibe coded but based loosely on UPIRs Code.

The code requirements are as follows:

- OTA Firmware Updates for remote upgrades/tweaks

- WIFI web server for debugging

- MQTT connection

- MQTT advertisement of variables

- GPIO Control (solenoid)

- 3x LED Panel Support

With these requirements and some example code I fed to chatGPT I got the following “finished” code.

Arduino Code, change variables to suit your needs.

/*

ESP32 Display + Dinger Combo (FULL)

- 3x Keyestudio 8x16 LED matrix panels stacked vertically => 8w x 48h

TOP: SCL=22 SDA=23

MID: SCL=18 SDA=19

BOTTOM: SCL=2 SDA=4

- Solenoid bell striker on GPIO15 (PULSE_PIN)

- MQTT discovery (SMALL payloads) for:

* Button: Ding

* Number: Ding count (1..3)

* Number: Pulse width (ms)

* Number: Gap (ms)

* Text: Display message (Home Assistant text entity)

- MQTT command topics (also usable directly):

* home/dinger/<deviceId>/ding/press payload: PRESS

* home/dinger/<deviceId>/ding_count/set payload: 1..3

* home/dinger/<deviceId>/pulse_width_ms/set payload: 1..2000

* home/dinger/<deviceId>/gap_ms/set payload: 0..5000

* home/dinger/<deviceId>/display/set payload: string

* home/dinger/<deviceId>/max_current/set payload: 0/1

- Web UI:

* Set count/width/gap + Ding

* Set display text

* Max-current test toggle (all LEDs on all panels)

- OTA enabled

Notes:

- GPIO15 is a strapping pin on some ESP32 boards; move if boot issues.

- Display scroll direction is TOP -> BOTTOM when message length > 6 chars (48/8).

*/

#include <Arduino.h>

#include <WiFi.h>

#include <PubSubClient.h>

#include <ArduinoOTA.h>

#include <WebServer.h>

// ---------- WIFI ----------

const char* WIFI_SSIDS[] = { "SSID1", "SSID2" };

const int WIFI_SSID_COUNT = sizeof(WIFI_SSIDS) / sizeof(WIFI_SSIDS[0]);

const char* WIFI_PASSWORD = "PASSWORD";

// ---------- MQTT ----------

const char* MQTT_HOST = "homeassistant.local";

const uint16_t MQTT_PORT = 1883;

const char* MQTT_USER = "MQTTUSER";

const char* MQTT_PASS = "MQTTPASS";

// OTA password

const char* OTA_PASSWORD = "OTAPASS";

#ifndef LED_BUILTIN

#define LED_BUILTIN 2

#endif

// ---------- HARDWARE ----------

static constexpr uint8_t PULSE_PIN = 15;

static constexpr uint8_t LED_PIN = LED_BUILTIN;

// 3 panels (top->bottom)

#define SCL_TOP 22

#define SDA_TOP 23

#define SCL_MID 18

#define SDA_MID 19

#define SCL_BOT 2

#define SDA_BOT 4

// ---------- DISPLAY GEOMETRY ----------

static const int PANEL_H = 16;

static const int PANELS = 3;

static const int DISP_H = PANEL_H * PANELS; // 48

// ---------- DING LIMITS ----------

static constexpr int DING_MIN = 1;

static constexpr int DING_MAX = 5;

static constexpr uint32_t PULSE_MIN_MS = 1;

static constexpr uint32_t PULSE_MAX_MS = 2000;

static constexpr uint32_t GAP_MIN_MS = 0;

static constexpr uint32_t GAP_MAX_MS = 5000;

// ---------- SCROLL ----------

static const uint16_t SCROLL_STEP_MS = 80;

static const uint16_t HOLD_MS = 800;

// ---------- GLOBALS ----------

WiFiClient espClient;

PubSubClient mqtt(espClient);

WebServer server(80);

int currentSsidIndex = 0;

// Dinger params

volatile int dingCount = 1;

volatile uint32_t pulseWidthMs = 20;

volatile uint32_t gapMs = 80;

// Dinger state machine (non-blocking, FIXED)

enum DingPhase : uint8_t { DING_IDLE, DING_PULSE_ON, DING_GAP_WAIT };

static DingPhase dingPhase = DING_IDLE;

static int dingRemaining = 0;

static uint32_t phaseUntilMs = 0;

// Display state

static const int MAX_MSG = 96;

char displayText[MAX_MSG] = "I LOVE YOU";

bool maxCurrentTest = false;

// Display buffers

static uint8_t fb[DISP_H]; // visible 48 rows (each row is 8 bits)

static uint8_t* vrows = nullptr; // virtual rows for scrolling

static int vheightAlloc = 0;

int scrollTopY = 0;

bool scrollHold = false;

uint32_t scrollLastStepMs = 0;

uint32_t scrollHoldStartMs = 0;

uint32_t displayEpoch = 0; // increment when text changes

uint32_t renderedEpoch = 0; // last rendered epoch

bool isScrolling = false;

// MQTT topics/IDs

char deviceId[32];

char baseTopic[96];

char availTopic[128];

char dingCmdTopic[128];

char countStateTopic[128];

char countCmdTopic[128];

char widthStateTopic[128];

char widthCmdTopic[128];

char gapStateTopic[128];

char gapCmdTopic[128];

// Display topics

char dispStateTopic[128];

char dispCmdTopic[128];

// Max current topics

char maxTestStateTopic[128];

char maxTestCmdTopic[128];

// Telemetry

uint32_t bootMs = 0;

uint32_t mqttReconnects = 0;

uint32_t lastMqttRxMs = 0;

char lastMqttTopic[128] = {0};

char lastMqttPayload[256] = {0};

// ---------- UTILS ----------

static int clampInt(int v, int lo, int hi) {

if (v < lo) return lo;

if (v > hi) return hi;

return v;

}

static uint32_t clampU32(uint32_t v, uint32_t lo, uint32_t hi) {

if (v < lo) return lo;

if (v > hi) return hi;

return v;

}

static void formatDeviceId() {

uint32_t macLo = (uint32_t)ESP.getEfuseMac();

snprintf(deviceId, sizeof(deviceId), "DINGER_%08X", macLo);

}

static void buildTopics() {

snprintf(baseTopic, sizeof(baseTopic), "home/dinger/%s", deviceId);

snprintf(availTopic, sizeof(availTopic), "%s/availability", baseTopic);

snprintf(dingCmdTopic, sizeof(dingCmdTopic), "%s/ding/press", baseTopic);

snprintf(countStateTopic, sizeof(countStateTopic), "%s/ding_count/state", baseTopic);

snprintf(countCmdTopic, sizeof(countCmdTopic), "%s/ding_count/set", baseTopic);

snprintf(widthStateTopic, sizeof(widthStateTopic), "%s/pulse_width_ms/state", baseTopic);

snprintf(widthCmdTopic, sizeof(widthCmdTopic), "%s/pulse_width_ms/set", baseTopic);

snprintf(gapStateTopic, sizeof(gapStateTopic), "%s/gap_ms/state", baseTopic);

snprintf(gapCmdTopic, sizeof(gapCmdTopic), "%s/gap_ms/set", baseTopic);

// Display

snprintf(dispStateTopic, sizeof(dispStateTopic), "%s/display/state", baseTopic);

snprintf(dispCmdTopic, sizeof(dispCmdTopic), "%s/display/set", baseTopic);

// Max current test

snprintf(maxTestStateTopic, sizeof(maxTestStateTopic), "%s/max_current/state", baseTopic);

snprintf(maxTestCmdTopic, sizeof(maxTestCmdTopic), "%s/max_current/set", baseTopic);

}

static void publishRetainedU32(const char* topic, uint32_t v) {

if (!mqtt.connected()) return;

char buf[16];

snprintf(buf, sizeof(buf), "%lu", (unsigned long)v);

mqtt.publish(topic, buf, true);

}

static void publishRetainedI32(const char* topic, int v) {

if (!mqtt.connected()) return;

char buf[16];

snprintf(buf, sizeof(buf), "%d", v);

mqtt.publish(topic, buf, true);

}

static void publishRetainedStr(const char* topic, const char* s) {

if (!mqtt.connected()) return;

mqtt.publish(topic, s, true);

}

static void publishRetainedBool(const char* topic, bool v) {

if (!mqtt.connected()) return;

mqtt.publish(topic, v ? "1" : "0", true);

}

// ---------- SOFTWARE I2C (bit-banged) ----------

void IIC_start(uint8_t scl, uint8_t sda) {

digitalWrite(scl, LOW); delayMicroseconds(3);

digitalWrite(sda, HIGH); delayMicroseconds(3);

digitalWrite(scl, HIGH); delayMicroseconds(3);

digitalWrite(sda, LOW); delayMicroseconds(3);

}

void IIC_send(uint8_t scl, uint8_t sda, uint8_t data) {

for (uint8_t i = 0; i < 8; i++) {

digitalWrite(scl, LOW); delayMicroseconds(3);

digitalWrite(sda, (data & 0x01) ? HIGH : LOW);

delayMicroseconds(3);

digitalWrite(scl, HIGH); delayMicroseconds(3);

data >>= 1;

}

}

void IIC_end(uint8_t scl, uint8_t sda) {

digitalWrite(scl, LOW); delayMicroseconds(3);

digitalWrite(sda, LOW); delayMicroseconds(3);

digitalWrite(scl, HIGH); delayMicroseconds(3);

digitalWrite(sda, HIGH); delayMicroseconds(3);

}

static void setBrightness(uint8_t scl, uint8_t sda, uint8_t brightnessCmd) {

IIC_start(scl, sda);

IIC_send(scl, sda, brightnessCmd); // 0x88..0x8F

IIC_end(scl, sda);

}

static void updateDisp(uint8_t scl, uint8_t sda, uint8_t frame16[16]) {

IIC_start(scl, sda);

IIC_send(scl, sda, 0x40); // auto-increment

IIC_end(scl, sda);

IIC_start(scl, sda);

IIC_send(scl, sda, 0xC0); // start addr 0

for (uint8_t i = 0; i < 16; i++) IIC_send(scl, sda, frame16[i]);

IIC_end(scl, sda);

}

// ---------- DISPLAY RENDERING ----------

static inline void fbClear() { memset(fb, 0, sizeof(fb)); }

// 8x8 font A-Z, 0-9, space

struct Glyph { char c; uint8_t rows[8]; };

static const Glyph font[] = {

{ ' ', {0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00} },

{ '0', {0x3C,0x66,0x6E,0x76,0x66,0x66,0x3C,0x00} },

{ '1', {0x18,0x38,0x18,0x18,0x18,0x18,0x3C,0x00} },

{ '2', {0x3C,0x66,0x06,0x0C,0x18,0x30,0x7E,0x00} },

{ '3', {0x3C,0x66,0x06,0x1C,0x06,0x66,0x3C,0x00} },

{ '4', {0x0C,0x1C,0x3C,0x6C,0x7E,0x0C,0x0C,0x00} },

{ '5', {0x7E,0x60,0x7C,0x06,0x06,0x66,0x3C,0x00} },

{ '6', {0x1C,0x30,0x60,0x7C,0x66,0x66,0x3C,0x00} },

{ '7', {0x7E,0x66,0x06,0x0C,0x18,0x18,0x18,0x00} },

{ '8', {0x3C,0x66,0x66,0x3C,0x66,0x66,0x3C,0x00} },

{ '9', {0x3C,0x66,0x66,0x3E,0x06,0x0C,0x38,0x00} },

{ 'A', {0x18,0x24,0x42,0x7E,0x42,0x42,0x42,0x00} },

{ 'B', {0x7C,0x42,0x42,0x7C,0x42,0x42,0x7C,0x00} },

{ 'C', {0x3C,0x42,0x40,0x40,0x40,0x42,0x3C,0x00} },

{ 'D', {0x78,0x44,0x42,0x42,0x42,0x44,0x78,0x00} },

{ 'E', {0x7E,0x40,0x40,0x7C,0x40,0x40,0x7E,0x00} },

{ 'F', {0x7E,0x40,0x40,0x7C,0x40,0x40,0x40,0x00} },

{ 'G', {0x3C,0x42,0x40,0x4E,0x42,0x42,0x3C,0x00} },

{ 'H', {0x42,0x42,0x42,0x7E,0x42,0x42,0x42,0x00} },

{ 'I', {0x7E,0x18,0x18,0x18,0x18,0x18,0x7E,0x00} },

{ 'J', {0x0E,0x04,0x04,0x04,0x44,0x44,0x38,0x00} },

{ 'K', {0x42,0x44,0x48,0x70,0x48,0x44,0x42,0x00} },

{ 'L', {0x40,0x40,0x40,0x40,0x40,0x40,0x7E,0x00} },

{ 'M', {0x42,0x66,0x5A,0x5A,0x42,0x42,0x42,0x00} },

{ 'N', {0x42,0x62,0x52,0x4A,0x46,0x42,0x42,0x00} },

{ 'O', {0x3C,0x42,0x42,0x42,0x42,0x42,0x3C,0x00} },

{ 'P', {0x7C,0x42,0x42,0x7C,0x40,0x40,0x40,0x00} },

{ 'Q', {0x3C,0x42,0x42,0x42,0x4A,0x44,0x3A,0x00} },

{ 'R', {0x7C,0x42,0x42,0x7C,0x48,0x44,0x42,0x00} },

{ 'S', {0x3C,0x42,0x40,0x3C,0x02,0x42,0x3C,0x00} },

{ 'T', {0x7E,0x18,0x18,0x18,0x18,0x18,0x18,0x00} },

{ 'U', {0x42,0x42,0x42,0x42,0x42,0x42,0x3C,0x00} },

{ 'V', {0x42,0x42,0x42,0x42,0x24,0x24,0x18,0x00} },

{ 'W', {0x42,0x42,0x42,0x5A,0x5A,0x66,0x42,0x00} },

{ 'X', {0x42,0x24,0x18,0x18,0x18,0x24,0x42,0x00} },

{ 'Y', {0x42,0x24,0x18,0x18,0x18,0x18,0x18,0x00} },

{ 'Z', {0x7E,0x02,0x04,0x18,0x20,0x40,0x7E,0x00} },

};

static const uint8_t* glyphRows(char c) {

if (c >= 'a' && c <= 'z') c = char(c - 'a' + 'A');

for (size_t i=0; i<sizeof(font)/sizeof(font[0]); i++) {

if (font[i].c == c) return font[i].rows;

}

return font[0].rows;

}

static int msgLen(const char* s) { int n=0; while (*s++) n++; return n; }

static void ensureVirtualHeight(int vheight) {

if (vheightAlloc == vheight && vrows) return;

if (vrows) free(vrows);

vrows = (uint8_t*)malloc(vheight);

vheightAlloc = vrows ? vheight : 0;

}

static void renderToVirtual(const char* msg) {

const int n = msgLen(msg);

const int messageHeight = n * 8; // 8px per char, no gap

const int vheight = messageHeight + DISP_H; // pad for entry/exit

ensureVirtualHeight(vheight);

if (!vrows) return;

memset(vrows, 0, vheight);

int y = 0;

for (const char* p = msg; *p; p++) {

const uint8_t* r = glyphRows(*p);

for (int dy=0; dy<8; dy++) {

int yy = y + dy;

if (yy >= 0 && yy < vheight) vrows[yy] = r[dy];

}

y += 8;

if (y >= vheight) break;

}

isScrolling = (n > (DISP_H / 8)); // >6 chars

scrollTopY = -DISP_H; // start above view

scrollHold = false;

scrollLastStepMs = millis();

}

static void windowFromVirtual(int topY) {

if (!vrows || vheightAlloc <= 0) { fbClear(); return; }

for (int y=0; y<DISP_H; y++) {

int srcY = topY + y;

fb[y] = (srcY >= 0 && srcY < vheightAlloc) ? vrows[srcY] : 0x00;

}

}

// If mirrored/flipped, fix ONLY here.

static void pushFbToPanels() {

uint8_t fTop[16], fMid[16], fBot[16];

for (int i=0; i<16; i++) fTop[i] = fb[0 + i];

for (int i=0; i<16; i++) fMid[i] = fb[16 + i];

for (int i=0; i<16; i++) fBot[i] = fb[32 + i];

updateDisp(SCL_TOP, SDA_TOP, fTop);

updateDisp(SCL_MID, SDA_MID, fMid);

updateDisp(SCL_BOT, SDA_BOT, fBot);

}

static void allLedsOnAllPanels() {

uint8_t on16[16];

for (int i=0; i<16; i++) on16[i] = 0xFF;

updateDisp(SCL_TOP, SDA_TOP, on16);

updateDisp(SCL_MID, SDA_MID, on16);

updateDisp(SCL_BOT, SDA_BOT, on16);

}

static void setDisplayText(const char* s) {

// sanitize to A-Z 0-9 space (unknown -> space)

size_t n = strnlen(s, MAX_MSG - 1);

for (size_t i = 0; i < n; i++) {

char c = s[i];

if (c >= 'a' && c <= 'z') c = char(c - 'a' + 'A');

bool ok = (c == ' ') || (c >= 'A' && c <= 'Z') || (c >= '0' && c <= '9');

displayText[i] = ok ? c : ' ';

}

displayText[n] = '\0';

displayEpoch++;

publishRetainedStr(dispStateTopic, displayText);

}

// ---------- DINGER (non-blocking, FIXED) ----------

static void startDings(int n) {

if (dingPhase != DING_IDLE) return;

n = clampInt(n, DING_MIN, DING_MAX);

dingRemaining = n;

dingPhase = DING_PULSE_ON;

phaseUntilMs = 0; // start immediately

}

static void serviceDinger() {

const uint32_t now = millis();

if (dingPhase == DING_IDLE) return;

if (phaseUntilMs && (int32_t)(now - phaseUntilMs) < 0) return;

const uint32_t w = clampU32(pulseWidthMs, PULSE_MIN_MS, PULSE_MAX_MS);

const uint32_t g = clampU32(gapMs, GAP_MIN_MS, GAP_MAX_MS);

switch (dingPhase) {

case DING_PULSE_ON:

// start pulse

digitalWrite(PULSE_PIN, HIGH);

digitalWrite(LED_PIN, HIGH);

dingPhase = DING_GAP_WAIT;

phaseUntilMs = now + w;

break;

case DING_GAP_WAIT:

// end pulse

digitalWrite(PULSE_PIN, LOW);

digitalWrite(LED_PIN, LOW);

dingRemaining--;

if (dingRemaining <= 0) {

dingPhase = DING_IDLE;

phaseUntilMs = 0;

} else {

// wait gap before next pulse

dingPhase = DING_PULSE_ON;

phaseUntilMs = now + g;

}

break;

default:

dingPhase = DING_IDLE;

phaseUntilMs = 0;

break;

}

}

// ---------- WIFI ----------

void connectWiFi() {

if (WiFi.status() == WL_CONNECTED) return;

WiFi.mode(WIFI_STA);

while (WiFi.status() != WL_CONNECTED) {

const char* ssid = WIFI_SSIDS[currentSsidIndex];

Serial.printf("Connecting to WiFi SSID: %s\n", ssid);

WiFi.begin(ssid, WIFI_PASSWORD);

int attempts = 0;

while (WiFi.status() != WL_CONNECTED && attempts < 20) {

delay(500);

Serial.print(".");

attempts++;

}

if (WiFi.status() == WL_CONNECTED) {

Serial.print("\nConnected to ");

Serial.print(ssid);

Serial.print(", IP=");

Serial.println(WiFi.localIP());

break;

} else {

Serial.printf("\nFailed to connect to %s\n", ssid);

currentSsidIndex = (currentSsidIndex + 1) % WIFI_SSID_COUNT;

delay(1000);

}

}

}

// ---------- MQTT DISCOVERY ----------

static void publishDiscoverySmall() {

if (!mqtt.connected()) return;

char cfgTopic[128];

char payload[256];

// Button (ding)

snprintf(cfgTopic, sizeof(cfgTopic), "homeassistant/button/%s/ding/config", deviceId);

snprintf(payload, sizeof(payload),

"{\"name\":\"%s Ding\",\"unique_id\":\"%s_ding\","

"\"command_topic\":\"%s\",\"payload_press\":\"PRESS\"}",

deviceId, deviceId, dingCmdTopic);

mqtt.publish(cfgTopic, payload, true);

// Number: Ding Count

snprintf(cfgTopic, sizeof(cfgTopic), "homeassistant/number/%s/ding_count/config", deviceId);

snprintf(payload, sizeof(payload),

"{\"name\":\"%s Ding Count\",\"unique_id\":\"%s_ding_count\","

"\"state_topic\":\"%s\",\"command_topic\":\"%s\","

"\"min\":1,\"max\":5,\"step\":1,\"mode\":\"slider\"}",

deviceId, deviceId, countStateTopic, countCmdTopic);

mqtt.publish(cfgTopic, payload, true);

// Number: Pulse Width (ms)

snprintf(cfgTopic, sizeof(cfgTopic), "homeassistant/number/%s/pulse_width_ms/config", deviceId);

snprintf(payload, sizeof(payload),

"{\"name\":\"%s Pulse Width (ms)\",\"unique_id\":\"%s_pulse_width_ms\","

"\"state_topic\":\"%s\",\"command_topic\":\"%s\","

"\"min\":%lu,\"max\":%lu,\"step\":1,\"mode\":\"slider\"}",

deviceId, deviceId, widthStateTopic, widthCmdTopic,

(unsigned long)PULSE_MIN_MS, (unsigned long)PULSE_MAX_MS);

mqtt.publish(cfgTopic, payload, true);

// Number: Gap (ms)

snprintf(cfgTopic, sizeof(cfgTopic), "homeassistant/number/%s/gap_ms/config", deviceId);

snprintf(payload, sizeof(payload),

"{\"name\":\"%s Gap (ms)\",\"unique_id\":\"%s_gap_ms\","

"\"state_topic\":\"%s\",\"command_topic\":\"%s\","

"\"min\":50,\"max\":500,\"step\":50,\"mode\":\"slider\"}",

deviceId, deviceId, gapStateTopic, gapCmdTopic,

(unsigned long)GAP_MIN_MS, (unsigned long)GAP_MAX_MS);

mqtt.publish(cfgTopic, payload, true);

// Text: Display Message (THIS MAKES text.<device>_display appear)

snprintf(cfgTopic, sizeof(cfgTopic), "homeassistant/text/%s/display/config", deviceId);

snprintf(payload, sizeof(payload),

"{\"name\":\"%s Display\",\"unique_id\":\"%s_display\","

"\"state_topic\":\"%s\",\"command_topic\":\"%s\","

"\"max\":95,\"mode\":\"text\"}",

deviceId, deviceId, dispStateTopic, dispCmdTopic);

mqtt.publish(cfgTopic, payload, true);

}

// ---------- MQTT CALLBACK ----------

void mqttCallback(char* topic, byte* payload, unsigned int length) {

lastMqttRxMs = millis();

strncpy(lastMqttTopic, topic, sizeof(lastMqttTopic) - 1);

lastMqttTopic[sizeof(lastMqttTopic) - 1] = '\0';

unsigned int n = (length < (sizeof(lastMqttPayload) - 1)) ? length : (sizeof(lastMqttPayload) - 1);

for (unsigned int i = 0; i < n; i++) lastMqttPayload[i] = (char)payload[i];

lastMqttPayload[n] = '\0';

if (strcmp(topic, countCmdTopic) == 0) {

dingCount = clampInt(atoi(lastMqttPayload), DING_MIN, DING_MAX);

publishRetainedI32(countStateTopic, dingCount);

return;

}

if (strcmp(topic, widthCmdTopic) == 0) {

pulseWidthMs = clampU32((uint32_t)atoi(lastMqttPayload), PULSE_MIN_MS, PULSE_MAX_MS);

publishRetainedU32(widthStateTopic, pulseWidthMs);

return;

}

if (strcmp(topic, gapCmdTopic) == 0) {

gapMs = clampU32((uint32_t)atoi(lastMqttPayload), GAP_MIN_MS, GAP_MAX_MS);

publishRetainedU32(gapStateTopic, gapMs);

return;

}

if (strcmp(topic, dingCmdTopic) == 0) {

startDings(dingCount);

return;

}

if (strcmp(topic, dispCmdTopic) == 0) {

setDisplayText(lastMqttPayload);

return;

}

if (strcmp(topic, maxTestCmdTopic) == 0) {

int v = atoi(lastMqttPayload);

maxCurrentTest = (v != 0);

publishRetainedBool(maxTestStateTopic, maxCurrentTest);

return;

}

}

void connectMQTT() {

mqtt.setServer(MQTT_HOST, MQTT_PORT);

mqtt.setCallback(mqttCallback);

mqtt.setBufferSize(512);

while (!mqtt.connected()) {

mqttReconnects++;

bool ok = mqtt.connect(

deviceId,

MQTT_USER,

MQTT_PASS,

availTopic,

0,

true,

"offline"

);

if (ok) {

mqtt.publish(availTopic, "online", true);

mqtt.subscribe(dingCmdTopic);

mqtt.subscribe(countCmdTopic);

mqtt.subscribe(widthCmdTopic);

mqtt.subscribe(gapCmdTopic);

mqtt.subscribe(dispCmdTopic);

mqtt.subscribe(maxTestCmdTopic);

publishDiscoverySmall();

publishRetainedI32(countStateTopic, dingCount);

publishRetainedU32(widthStateTopic, pulseWidthMs);

publishRetainedU32(gapStateTopic, gapMs);

publishRetainedStr(dispStateTopic, displayText);

publishRetainedBool(maxTestStateTopic, maxCurrentTest);

} else {

Serial.print("MQTT failed rc=");

Serial.println(mqtt.state());

delay(2000);

}

}

}

// ---------- WEB ----------

static String statusJson() {

bool wifiOk = (WiFi.status() == WL_CONNECTED);

bool mqttOk = mqtt.connected();

int rssi = wifiOk ? WiFi.RSSI() : -999;

uint32_t upS = (millis() - bootMs) / 1000;

uint32_t lastAgeMs = (lastMqttRxMs == 0) ? 0 : (millis() - lastMqttRxMs);

String ip = wifiOk ? WiFi.localIP().toString() : "0.0.0.0";

String j;

j.reserve(1000);

j += "{";

j += "\"device_id\":\""; j += deviceId; j += "\",";

j += "\"ip\":\""; j += ip; j += "\",";

j += "\"rssi\":"; j += String(rssi); j += ",";

j += "\"mqtt_connected\":"; j += (mqttOk ? "true" : "false"); j += ",";

j += "\"mqtt_state\":"; j += String(mqtt.state()); j += ",";

j += "\"mqtt_reconnects\":"; j += String(mqttReconnects); j += ",";

j += "\"ding_count\":"; j += String(dingCount); j += ",";

j += "\"pulse_width_ms\":"; j += String(pulseWidthMs); j += ",";

j += "\"gap_ms\":"; j += String(gapMs); j += ",";

j += "\"ding_phase\":"; j += String((int)dingPhase); j += ",";

j += "\"display_text\":\""; j += displayText; j += "\",";

j += "\"max_current_test\":"; j += (maxCurrentTest ? "true" : "false"); j += ",";

j += "\"uptime_s\":"; j += String(upS); j += ",";

j += "\"last_mqtt_topic\":\""; j += lastMqttTopic; j += "\",";

j += "\"last_mqtt_payload\":\""; j += lastMqttPayload; j += "\",";

j += "\"last_mqtt_age_ms\":"; j += String(lastAgeMs);

j += "}";

return j;

}

void handleRoot() {

server.send(200, "text/html",

"<!doctype html><html><head><meta name='viewport' content='width=device-width,initial-scale=1'>"

"<title>Dinger + Display</title>"

"<style>body{font-family:system-ui;margin:20px;max-width:860px}"

"input{font-size:18px;padding:6px 8px} "

"button{font-size:18px;padding:10px 16px;margin:6px 8px 6px 0} "

"pre{background:#111;color:#eee;padding:12px;border-radius:10px;overflow:auto}"

".row{margin:10px 0}</style></head><body>"

"<h2>Dinger + Display</h2>"

"<div class='row'>Ding count (1..3): <input id='count' type='number' min='1' max='3' step='1'></div>"

"<div class='row'>Pulse width (ms): <input id='width' type='number' min='1' step='1'></div>"

"<div class='row'>Gap (ms): <input id='gap' type='number' min='0' step='1'></div>"

"<button onclick='applyDing()'>Apply</button>"

"<button onclick='fire()'>Ding</button>"

"<hr>"

"<div class='row'>Display text: <input id='msg' type='text' style='width:420px' maxlength='95'></div>"

"<button onclick='applyMsg()'>Set Display</button>"

"<button onclick='maxOn()'>Max Current ON</button>"

"<button onclick='maxOff()'>Max Current OFF</button>"

"<h3>Status</h3><pre id='st'>loading...</pre>"

"<script>"

"async function getStatus(){"

" const r=await fetch('/status'); const j=await r.json();"

" document.getElementById('st').textContent=JSON.stringify(j,null,2);"

" if(document.activeElement.id!=='count') document.getElementById('count').value=j.ding_count;"

" if(document.activeElement.id!=='width') document.getElementById('width').value=j.pulse_width_ms;"

" if(document.activeElement.id!=='gap') document.getElementById('gap').value=j.gap_ms;"

" if(document.activeElement.id!=='msg') document.getElementById('msg').value=j.display_text;"

"}"

"async function applyDing(){"

" const c=document.getElementById('count').value|0;"

" const w=document.getElementById('width').value|0;"

" const g=document.getElementById('gap').value|0;"

" await fetch(`/set_ding?count=${c}&width=${w}&gap=${g}`); await getStatus();"

"}"

"async function fire(){ await fetch('/fire'); await getStatus(); }"

"async function applyMsg(){"

" const m=encodeURIComponent(document.getElementById('msg').value);"

" await fetch(`/set_msg?m=${m}`); await getStatus();"

"}"

"async function maxOn(){ await fetch('/max?on=1'); await getStatus(); }"

"async function maxOff(){ await fetch('/max?on=0'); await getStatus(); }"

"setInterval(getStatus,1000); getStatus();"

"</script></body></html>"

);

}

void handleStatus() { server.send(200, "application/json", statusJson()); }

void handleSetDing() {

if (server.hasArg("count")) dingCount = clampInt(server.arg("count").toInt(), DING_MIN, DING_MAX);

if (server.hasArg("width")) pulseWidthMs = clampU32((uint32_t)server.arg("width").toInt(), PULSE_MIN_MS, PULSE_MAX_MS);

if (server.hasArg("gap")) gapMs = clampU32((uint32_t)server.arg("gap").toInt(), GAP_MIN_MS, GAP_MAX_MS);

publishRetainedI32(countStateTopic, dingCount);

publishRetainedU32(widthStateTopic, pulseWidthMs);

publishRetainedU32(gapStateTopic, gapMs);

server.send(200, "text/plain", "OK");

}

void handleFire() {

startDings(dingCount);

server.send(200, "text/plain", "OK");

}

void handleSetMsg() {

if (server.hasArg("m")) {

String m = server.arg("m"); // decoded

setDisplayText(m.c_str());

}

server.send(200, "text/plain", "OK");

}

void handleMax() {

int on = server.hasArg("on") ? server.arg("on").toInt() : 0;

maxCurrentTest = (on != 0);

publishRetainedBool(maxTestStateTopic, maxCurrentTest);

server.send(200, "text/plain", "OK");

}

// ---------- DISPLAY SERVICE (non-blocking) ----------

static void serviceDisplay() {

if (maxCurrentTest) {

allLedsOnAllPanels();

return;

}

if (renderedEpoch != displayEpoch) {

renderToVirtual(displayText);

renderedEpoch = displayEpoch;

}

const uint32_t now = millis();

if (!isScrolling) {

fbClear();

int n = msgLen(displayText);

int maxStatic = DISP_H / 8; // 6

for (int i=0; i<n && i<maxStatic; i++) {

const uint8_t* r = glyphRows(displayText[i]);

for (int dy=0; dy<8; dy++) {

fb[i*8 + dy] = r[dy];

}

}

pushFbToPanels();

return;

}

if (scrollHold) {

if (now - scrollHoldStartMs >= HOLD_MS) {

scrollHold = false;

scrollLastStepMs = now;

} else {

windowFromVirtual(scrollTopY);

pushFbToPanels();

return;

}

}

if (now - scrollLastStepMs >= SCROLL_STEP_MS) {

scrollLastStepMs = now;

scrollTopY++; // TOP -> BOTTOM

if (vrows && vheightAlloc > 0) {

if (scrollTopY > (vheightAlloc - DISP_H)) {

scrollTopY = -DISP_H;

scrollHold = true;

scrollHoldStartMs = now;

}

}

}

windowFromVirtual(scrollTopY);

pushFbToPanels();

}

// ---------- OTA ----------

static void setupOTA() {

ArduinoOTA.setHostname(deviceId);

if (OTA_PASSWORD && OTA_PASSWORD[0] != '\0') ArduinoOTA.setPassword(OTA_PASSWORD);

ArduinoOTA.begin();

}

// ---------- SETUP / LOOP ----------

void setup() {

Serial.begin(115200);

delay(300);

bootMs = millis();

// Dinger pins

pinMode(PULSE_PIN, OUTPUT);

digitalWrite(PULSE_PIN, LOW);

pinMode(LED_PIN, OUTPUT);

digitalWrite(LED_PIN, LOW);

// Display pins

pinMode(SCL_TOP, OUTPUT); pinMode(SDA_TOP, OUTPUT);

pinMode(SCL_MID, OUTPUT); pinMode(SDA_MID, OUTPUT);

pinMode(SCL_BOT, OUTPUT); pinMode(SDA_BOT, OUTPUT);

digitalWrite(SCL_TOP, LOW); digitalWrite(SDA_TOP, LOW);

digitalWrite(SCL_MID, LOW); digitalWrite(SDA_MID, LOW);

digitalWrite(SCL_BOT, LOW); digitalWrite(SDA_BOT, LOW);

// Brightness

setBrightness(SCL_TOP, SDA_TOP, 0x8E);

setBrightness(SCL_MID, SDA_MID, 0x8E);

setBrightness(SCL_BOT, SDA_BOT, 0x8E);

// IDs/topics

formatDeviceId();

buildTopics();

// WiFi

connectWiFi();

// OTA

setupOTA();

// MQTT

mqtt.setCallback(mqttCallback);

connectMQTT();

// Web

server.on("/", handleRoot);

server.on("/status", handleStatus);

server.on("/set_ding", handleSetDing);

server.on("/fire", handleFire);

server.on("/set_msg", handleSetMsg);

server.on("/max", handleMax);

server.begin();

// Init display

setDisplayText(displayText);

renderToVirtual(displayText);

renderedEpoch = displayEpoch;

}

void loop() {

ArduinoOTA.handle();

if (WiFi.status() != WL_CONNECTED) connectWiFi();

if (!mqtt.connected()) connectMQTT();

mqtt.loop();

server.handleClient();

serviceDinger();

serviceDisplay();

}

Wifi supports multiple networks. So you can test and deploy between multiple locations (like if you’re giving this to a friend).

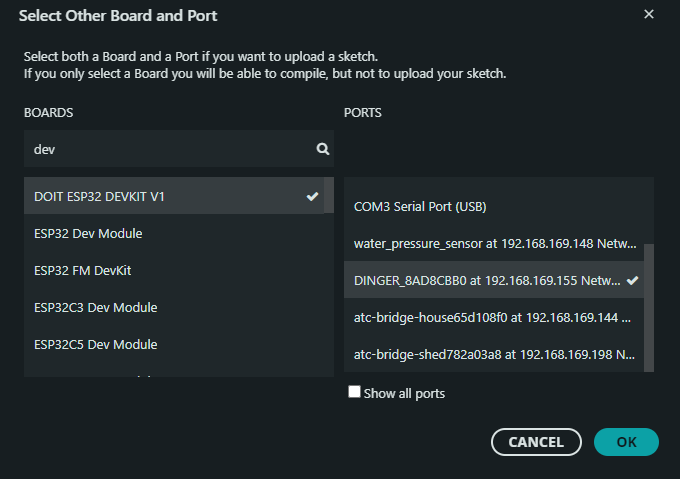

The board to use for these generic ESP-32’s is DOIT ESP32 DEVKIT V1

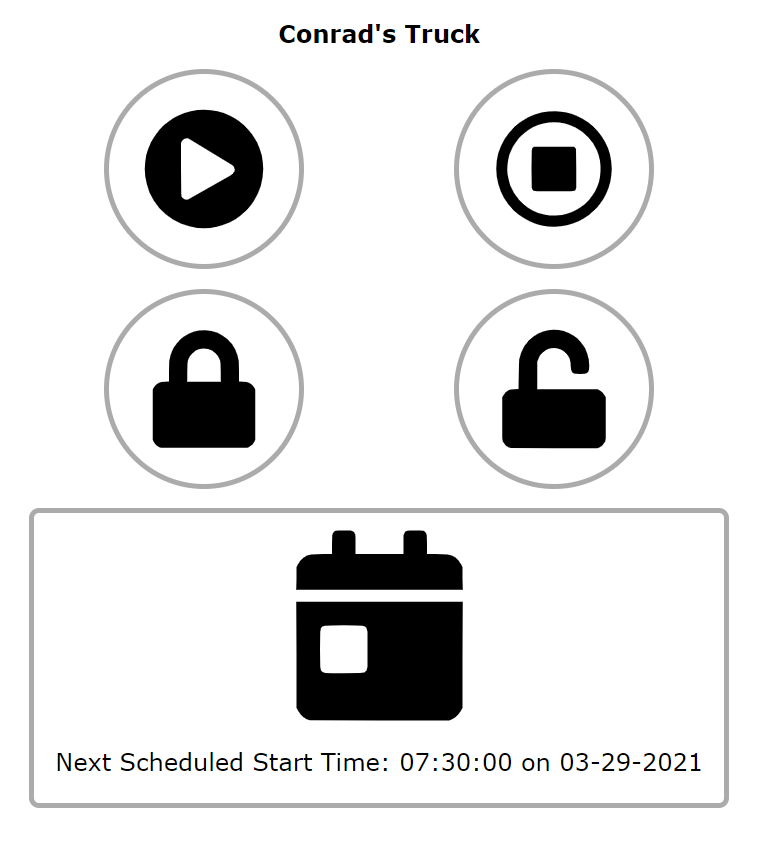

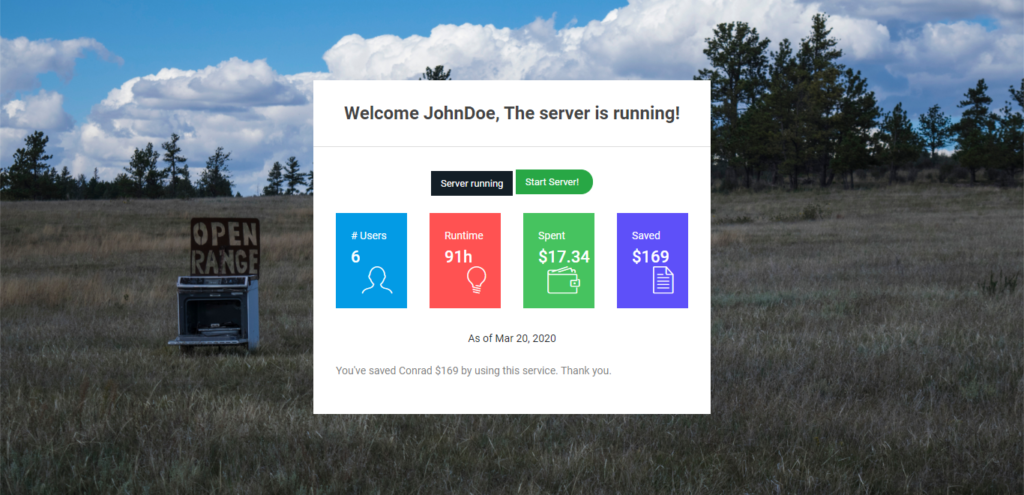

Home Assistant Integration

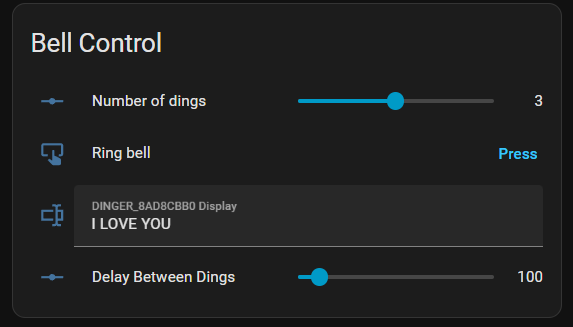

Since the code above contains auto-discovery you can easily write your own dashboard for this unit. The main breakouts are:

- Ding

- Ding Count

- Pulse Width (how long the solenoid stays on for)

- Gap (gap between dings)

- Text (display message)

Once the MQTT “sensors” are discovered you can make a quick dashboard to test out basic functionality. Keep in mind that the “dinger” sensor is followed by the ESP’s MAC address so you can have multiple of these units. The below HomeAssistant integration code won’t work for you, but you should be able to use your own mac address (advertised) and be up and running.

Bell Control Dashboard Code

type: entities

title: Bell Control

entities:

- entity: number.dinger_8ad8cbb0_ding_count

name: Number of dings

- entity: button.dinger_8ad8cbb0_ding

name: Ring bell

- entity: text.dinger_8ad8cbb0_display

- entity: number.dinger_8ad8cbb0_gap_ms

name: Delay Between Dings

grid_options:

columns: 12

rows: auto

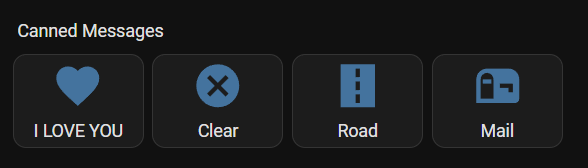

Once you’re happy with the manual control, you’ll want to get some automation hooks in. This allows for 1-press canned messages and for integration with other sensors (like a mailbox or road sensor).

Canned Messages Dashboard Code

type: horizontal-stack

cards:

- show_name: true

show_icon: true

type: button

name: I LOVE YOU

icon: mdi:heart

tap_action:

action: perform-action

target:

entity_id: automation.dinger_love_you

perform_action: automation.trigger

data:

skip_condition: true

- type: button

name: Clear

icon: mdi:close-circle

tap_action:

action: call-service

service: automation.trigger

target:

entity_id: automation.dinger_clear_display

- type: button

name: Road

icon: mdi:road

tap_action:

action: call-service

service: automation.trigger

target:

entitity_id: automation.road_notification_dinger

- type: button

name: Mail

icon: mdi:mailbox

tap_action:

action: call-service

service: automation.trigger

target:

entitity_id: automation.mail

For the canned messages to work, you need to have automations written on the back end for each of the buttons to call. Here are a couple automations you can use:

Clear Automation (Clears the LED Display)

alias: dinger_clear_display

description: ""

triggers:

- trigger: event

event_type: ""

conditions: []

actions:

- action: text.set_value

metadata: {}

target:

entity_id: text.dinger_8ad8cbb0_display

data:

value: ""

mode: single

I LOVE YOU Automation (Dings the bell 3 times, and displays “I LOVE YOU” on the LED Display)

alias: dinger_love_you

description: ""

triggers:

- trigger: event

event_type: ""

conditions: []

actions:

- action: text.set_value

metadata: {}

target:

entity_id: text.dinger_8ad8cbb0_display

data:

value: I LOVE YOU

- action: number.set_value

metadata: {}

target:

entity_id: number.dinger_8ad8cbb0_ding_count

data:

value: "3"

- action: button.press

metadata: {}

target:

entity_id: button.dinger_8ad8cbb0_ding

data: {}

mode: single

Project Files

My code is pasted above in the Code section. The 3D files are available for download, modification, or printing on Printables and MakerWorld.

Final Thoughts

The ! Notifier was fun to design and I hope to see others use or remix the design for their own use!

Errata

The ESP32 I use works just great when called a “DOIT ESP32 DEVKIT V1” that’s not what it’s called on amazon.